Cryogenic food solutions

When your customers want: flexibility, quality and economy

Discover the top five benefits of cryogenic refrigeration

- Quality

Perfect results in record time: Cooling or cryogenic freezing takes place particularly quickly, perfectly preserving the taste and the freshness of food.

- Flexibility

Multifunctional and compact: the same cryogenic equipment can cool, freeze and harden a surface... and thus ensure optimal flexibility of your production line.

- Productivity

Food grade cryogenics allows continuous adjustment of cooling capacity, reduced water loss and up to 10 times faster product processing time. You can run your equipment continuously at the nominal flow rate, while perfectly preserving your product quality.

- Performance

Save time: Combine cryogenic refrigeration with mechanical refrigeration for even faster cooling and freezing.

- Innovation

Create and market new products in varying quantities - based on demand - and with less investment.

A wide range of applications

Cryogenic techniques are also increasingly being used in molecular cooking, and to create effects around the food (smoke, etc.)

Batch or continuous rapid freezing, IQF, encrusting or forming, rapid cooling and food transport... A range of applications, equipment and gases (CO 2 and nitrogen) for cryogenic applications in the food industry.

To guarantee the integrity of the cold chain from producer to consumer, Air Liquide offers reliable, quiet and ecological cryogenic solutions.

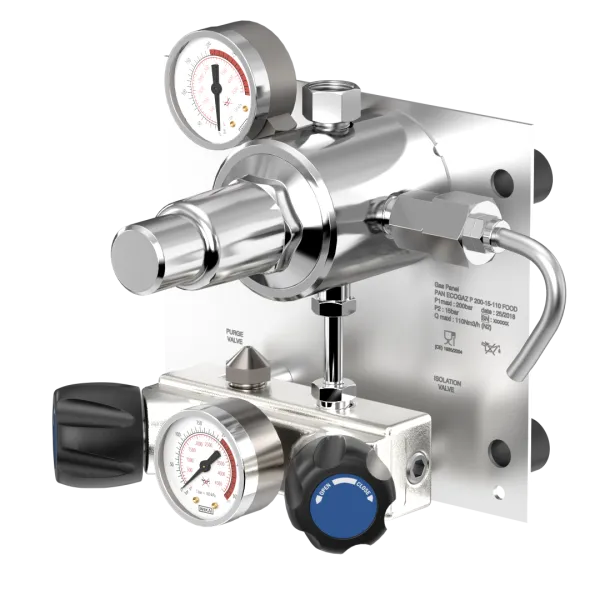

Food grade gas & equipment

Do you have any questions about gases or equipment for food cryogenics?

Please fill in our contact form below and we'll come back to you as soon as possible.