The food to be treated is introduced into this cooling or deep-freezing cell by ladders (or trolleys) made up of plates, grids, shelves or trays depending on the type of food to be introduced. They are equipped with a temperature sensor which enables direct monitoring of the cold descent speed as well as the maintenance of the temperature inside the cold cell. It is also a means of regulating the supply of cold. An additional temperature probe (in direct contact with the product) can also be installed in this type of device to monitor the descent into the cold of the food during the cooling or freezing process.

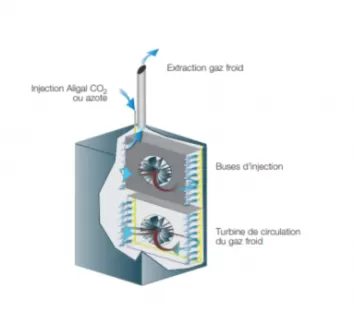

The presence of fans makes it possible, with an adaptation of their speed, to improve heat transfers and therefore consumption and Batch times. This forced convection technology creates homogeneity in the processing of food products. The production parameters (ventilation, temperature, processing time, etc.), and the phases, are chosen and recorded in recipes adapted to each product, which makes it possible to quickly start mass production.

The blast freezing cells have inlets designed to inject cryogenic gases, extractions to evacuate them, appropriate safety devices and high-performance thermal insulation which make it possible to limit cold losses and limit consumption.

Why use a blast chiller ?

The rapid cooling technology integrated in the rapid cells makes it possible to limit the proliferation of micro-organisms (bacteria, yeasts, fungi, parasites) thanks to the reduction of the time during which the product is in temperature zones favoring their multiplication.

These machines also make it possible to obtain better preservation of the organoleptic properties of food products. This applies to food whether unprocessed or cooked, whether fresh (+4°C) or warmer. This rapid deep freezing guarantees a rapid change in the state of the free water present in the food. The integrity of the biological cells is therefore preserved, which allows the conservation of the texture and maintenance of the weight of the products (little or no dehydration). The rapid decrease in temperature therefore makes it possible to avoid the exudates and the degradation of the texture of the foodstuffs usually observed on products frozen at slow speed.

These rapid cold cells therefore allow the cooling and freezing of food by cycle or batch while preserving all the qualities of the food (aromas, taste, texture), nutritional quality and microbiological safety.

Why does cryogenics make it possible to offer rapid cooling equipment?

Professional cryogenic freezing cells will use liquid nitrogen or liquid carbon dioxide to operate.

The application of extreme temperatures in cryogenic cells (up to -130°C for nitrogen and -65°C for CO2), in direct contact with food, allows cooling or freezing at a rapid rate and allows you to achieve an incredibly reduced processing time.

Specific cooling and freezing cells have been developed and adapted to the requirements of the food industries.

The CRYO CABINET

Air Liquide recommends the CRYO CABINET or cryogenic cell model, designed for the batch freezing and cooling of food products (in particular for meat, fish, prepared meals, fruit and vegetables, pastries, savory or sweet snacks, etc.), has an entirely welded stainless steel structure (without retention zone), rounded interior corners, a ventilation system preventing any condensation and high-performance removable edge seals which are the subject of 2 patents filed by Air Liquide .

Due to its innovative design, the CRYO CABINET has very concrete advantages for players in the food industry: a short-lasting freezer, optimized gas consumption and reduced cleaning time. This equipment provides particularly innovative responses to the needs of food manufacturers, particularly in terms of hygiene, ergonomics and performance.

The CRYO CABINET is ideal for processors who need better productivity and ease of use with minimal investment and installation cost.

Our professional cryogenic cells can be easily integrated into any batch process

Once the process with the blast chiller has passed, restaurants or catering professionals can use different models of cold room, refrigeration, or freezer, in the back of the shop or kitchen (to facilitate access for preparations), or at the level showcases.

Discover our solutions

Do you have any questions about the cryo cabinet?

Please complete our contact form below and we'll come back to you as soon as possible.