The benefits of cryogenic food refrigeration

Supply of food grade gases such as liquid nitrogen or CO2

Two gases are used in the cryogenic cooling process:

- Food grade nitrogen (N2)

- Food grade carbon dioxide (CO2)

Air Liquide helps you choose the right cryogenic liquid, depending on your process, the gases already present on your site, and your geographic location.

All our cryogenic food grade gases are ISO 22000 certified.

Food grade equipment for your products

Air Liquide offers two types of solutions to cool your products:

- Installation of our cooling equipment in your production line (tunnel, cell), and/or

- The integration of our materials to bring cold to your own equipment

Our expertise at your service

In addition to the simple supply of gas and the technical control of cryogenic processes, Air Liquide supports and advises you with your entire project, up to the commissioning in production and the maintenance of your equipment.

Our experience is:

- More than 1,200 worldwide references

- Food experts working in a global network. A local team dedicated to your project

Temperature control at every stage of the manufacturing process

In addition to maintaining product quality, refrigeration and temperature control operations make it possible to optimise industrial processes and handle complex products.

|

Operation |

Role of the cryogenic process |

Examples |

|---|---|---|

|

hash |

Compensate for heat input

|

Meat, processed poultry. |

|

Grinding |

Control the particle size of the |

Spices, fats, vegetables seeds. |

| Slicing |

Freezing of soft products |

Fish, ham, creamy bisucits |

| Grating |

Control the temperature when |

Grated or diced cheese. |

| Kneading |

Compensate for heat input |

Bakery products, fresh pasta. |

| Mixing |

Ensure the homogenity of the |

Processed meats and poultry |

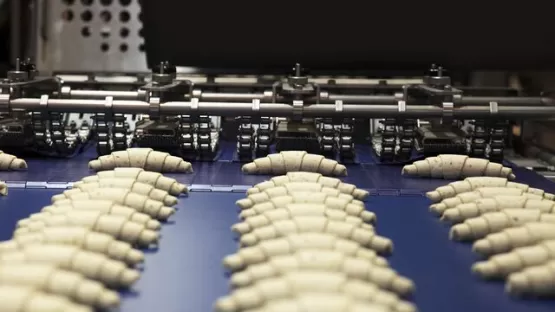

| Forming |

Shape retention by hardening |

Ice creams, extruded vegetable proteins |

| Coating |

Limitation of the phenomena of diffusion |

Fried meat or vegetables. |

| Heat treatment |

Cooling of the product befoe |

Cooked meals, vegetable proteins. |

| Dosage |

Control the flow of products without |

Mix of vegetables, powders, |

A range of specialised food grade gases and equipment

Do you have any questions about gases or equipment for cryogenic cooling?

Please complete our contact form below and we will get back to you as soon as possible.