Why choose Air Liquide's food grade gases?

|

|

Quality, food safety and traceabilityEach of our food grade gases complies with local regulations and is subject to the same Air Liquide requirements in terms of minimum specifications and manufacturing standards to be respected throughout the world. Our food grade gases guarantee that the process from production to delivery of gases follows HACCP principles to identify, assess and control any potential food safety incident. A traceability system with batch recall is in place if necessary. |

|

|

Reliability and continuity of supplyOur food grade gases guarantee the same quality, conformity and reliability of our products, everywhere in the world. Our food grade gases are available in a variety of forms, ranging from high pressure cylinders for small volume requirements to cryogenic liquid gas storage tanks for larger requirements, with the ability to produce gas mixtures on site . Our mode of supply can be easily modulated to meet the evolving needs of our customers. Our production sites spread throughout the territory and close to our customers ensure a reliable supply. We also offer our customers an automatic replenishment service thanks to remote gas level monitoring. |

|

|

Expertise and supportWith solid experience in the food and beverage industries, our team of specialists knows how to make the most of our R&D capabilities and Air Liquide's know-how to support our customers in the development of new and innovative products. Thanks to a detailed knowledge of the interactions between gases and food products, our process experts design appropriate solutions allowing our customers to optimize product quality and process efficiency while minimising operational costs. |

A wide range of food gases

Food grade gases for food packaging and processing

Air Liquide offers a premium range of food grade gases for food processing applications. Food grade gases are used for many processes, including:

- Modified atmosphere packaging (MAP)

- Cryogenic cooling and freezing of food

- IQF crusting and freezing

- Stunning animals

- Refrigerated transport

The properties of our food grade gases are also ideal for protecting edible oils against oxidation, manufacturing food powders by cryogenic grinding, adjusting the pH of dairy products, whipping creamy products or stabilising food ingredients. Our food grade gases allow a natural processing solution that does not modify the original composition of food.

Our range of food grade gases are composed of pure gases and mixtures to obtain the desired properties

- Nitrogen (N₂) : Nitrogen protects products against oxidation, limits the development of aerobic bacteria, prevents deformation of packaging.

- Carbon Dioxide (CO₂) : Carbon dioxide helps to give a sparkling and tart taste in drinks, limits the development of aerobic bacteria and slows the development of molds.

- Oxygen (O₂) : Oxygen keeps fresh products breathing, limits the development of anaerobic bacteria, and preserves the colour of red meats.

- Argon (Ar) : Like nitrogen, argon protects products against oxidation, limits the development of aerobic bacteria and prevents deformation of packaging. It reduces enzymatic degradation.

- Liquid Nitrogen (-196°C) and liquid Carbon Dioxide (-78.5°C): these cryogenic gases provide the cooling power necessary for freezing or rapid cooling of the product while preserving its texture.

Food grade gases for making beverages

Our range of food grade gases is also used in the preperation and packaging of beverages, in particular for:

- Carbonation

- Inerting (blanketing) and purging of tanks

- Deoxygenation (stripping)

- Protecting wine quality, from vine to glass, by optimising dissolved oxygen and carbon dioxide levels

- Draft beer racking

Regulation and traceability of food grade gases

Our food grade gases comply with current food safety regulations:

- European regulations on food additives

- Compliance with the HACCP approach

- Guarantee of traceability

Beyond regulatory compliance and to meet the specific requirements of our customers, our food grade gases are manufactured, delivered and implemented in compliance with international standards recognised in the food industry such as ISO 22000, FSSC 22000 (Food Safety System Certification).

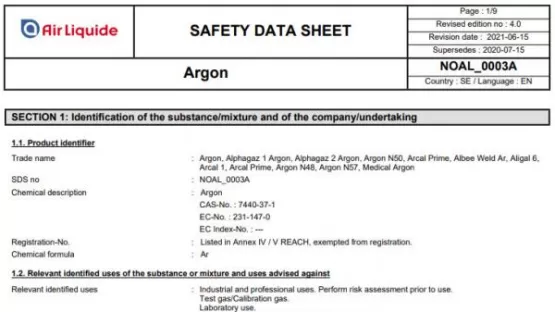

Safety Documentation

Gas safety data sheets (MSDS)

Find the reference document you need.

Modes of delivery

Do you have any questions about food grade gases?

Please complete our contact form below and we'll come back to you as soon as possible.