Our cryogenic freezing solution for food products brings you:

|

|

Safeguard the freshness, texture and flavour of productsThanks to a very rapid drop in temperature at the core, cryogenic freezing ensures micro crystallization of water in the cells, preserving there integrity and the texture of food products. |

|

|

Flexibility and productivity gainsCryogenic equipment can adapt to any change in production, by adjusting the flow rate and the set temperature of the fluid. In addition, since water losses linked to dehydration are limited, your product yield is optimised. |

|

|

Space saving and ease of integrationAt power equivalent to conventional mechanical cold, cryogenic equipment is less bulky and can be adapted to many configurations. Simple in design, they are quickly operational and fit naturally into the existing production line. |

|

|

Optimised utilisation rateCryogenic equipment is mechanically very simple, without a compressor, which implies less maintenance, less defrosting. Easy and fast cleaning is due to the better accessibility. This reduces downtime. |

Our cryogenic freezing solution for food products optimses the performance of your products

With Air Liquide, benefit from complete cryogenic freezing solutions adapted to your

manufacturing process, combining gas, equipment and technical expertise.

Supply of food grade liquid Nitrogen

In the cryogenic freezing process, liquid nitrogen is the main gas used. To meet current food safety requirements and regulations, Air Liquide offers food grade Nitrogen, ISO 22000 certified.

Our equipment for your food products

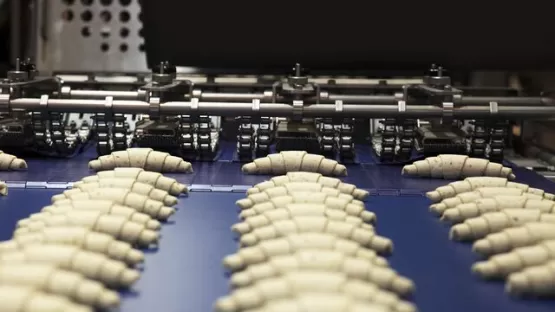

Air Liquide offers a wide range of freezing equipment to meet strict hygiene and food safety standards, and operate efficiently and sustainably:

- Cabinets or cells for discontinuous freezing (batch).

- Linear tunnels, mono-belt and multi-belt, for continuous freezing.

- Specific equipment for freezing IQF products, for coating, solidifying fat, etc.

Our expertise and experience at your service

Our expertise covers project management, budget approach, equipment installation, commissioning, and after-sales service. An innovation, a new process need?

We provide a variety of resources: modeling tools, tests, Research and Development teams, network of equipment partners, etc.

Our experience is:

- Over 40 years of innovation in food cryogenics

- More than 1,200 worldwide references

- A local local team dedicated to your project

There is a solution for every cooling need

To support the diversification of the offer in the agri-food sector, Air Liquide has developed innovative cryogenic solutions for freezing all types of food, both solid and liquid.

| Application | Equipment | Type | Gas |

|---|---|---|---|

| Freezing | Cryo Cabinet | Cell (batch) | Food grade freeze 1 Food grade freeze 2 |

| Cryo Tunnel - FP1 |

Stainless steel belt tunnel (continuous) |

||

| Cryo Tunnel - ZF3 | |||

| Cryo Tunnel - EZ1 | |||

| Cryo Tunnel - EZ1M | Multi-pass tunnel | ||

| Cryo Tunnel - MP1 | Multi-belt tunnel with product reversal | ||

| Cryo Drop | Bulk mixer | ||

| Cryo Tunnel - CFP | Polyester carpet tunnel (continuous) | Food grade freeze 1 | |

| Cryo Cristallizer - M | Liquid nitrogen spray enclosure | ||

| IQF freezing | Cryo Tunnel - MP1 | Multi-belt tunnel with product reversal | Food grade freeze 1 Food grade freeze 2 |

| Cryo Tunnel - ZR2 | Perforated rotary drum | ||

| Cryo Immersion Unit - CFB | Vibrating trough | Food grade freeze 1 | |

| Cryo Injector - CB3 | Injector for mixer by low injection | Food grade freeze 1 Food grade freeze 2 |

Cryogenic cold Vs mechanical cold

If mechanical refrigeration is a very widespread technology, cryogenic refrigeration offers many advantages, sometimes unrecognized, in terms of product quality, freezing speed, flexibility of installations. Air Liquide explains the advantages of cryogenic cold and the difference with mechanical cold.

A range of dedicated food grade gases and equipment

Food freezing, IQF freezing: a range of food-grade gases, and innovative application equipment.

Do you have any questions about our gas or equpment solutions for cryogenic freezing?

Please complete our contact form below and we'll come back to you as soon as possible.