Varied and innovative solutions with expert support

The global boom in individual mobility is reflected in a significant increase in car production. At the same time, players in the automotive industry are subject to very strict requirements in terms of safety and respect for the environment.

These requirements encourage manufacturers and equipment manufacturers to take an interest in the development of lighter materials and new engines (electric or powered by fuel cells).

Air Liquide allows them to constantly innovate – in materials, design, manufacturing, new technologies – to respond to these market developments. Our solutions cover a wide spectrum of applications for your production and control operations and are compatible with your quality assurance systems.

Compliance with standards and quality

The purity, precision, reliability and speed of delivery of our specialty gases improves analytical reliability for increased compliance assurance.

Air Liquide produces gases in a range of purity to meet your needs. We can provide the analysis of certain impurities on request.

In order to protect the environment and our health regulatory authorities are imposing more stringent regulations on vehicle manufacturers in Europe and worldwide. As a consequence, engine manufacturers, their suppliers and testing centres need to perform more rigorous emissions analysis. We have listened to you and understood what your key expectations are:

- Compliance with legislation

- Documentation and traceability

- Reduced lead time

- Reduced downtime between test cycles – better efficiency

- Lowest total cost of ownership

Where vehicle manufacturers in the past were mainly concerned with national laws, the manufacturing and sale of vehicles is now truly global. Manufacturers in Europe are not only faced with EU legislation, many are today also concerned by EPA (USA) compliance.

Our calibration mixtures and pure gases are fully compliant to current EPA (CFR 40 Part 1065/1066) and EURO norms (EURO 5, 6a, 6b, 6c) and we can also offer dual compliant gases in a single cylinder.

In addition to this, companies and customers are aiming to increase efficiency and reduce errors in their testing. Changing a single cylinder or a pack on a central gas supply can dramatically impact the analytical performance of the equipment. Air Liquide’s unique batch manufacturing and cylinder treatment technologies of mixtures alleviates this issue by enabling batches of identical mixtures to be produced. This allows you to concentrate on testing and achieving homologation and engine approval.

Air Liquide today offers electronic certificates enabling customers to store and retrieve certificates easily. We also offer solutions that allow you perform automatic calibration of the analytical equipment by importing the certificate automatically.

This is an efficient way to reduce human errors and enhance reliability of analytical values, as well as speeding up the analysis preparation.

Sustainable solutions

Our product brands ARCAL™, LASAL™ for metal fabrication have been designed with a view to preserving the environment with the reduction of carbon dioxide and nitrogen oxide emissions.

Varied offer and innovation

Air Liquide experts in the industrial sector are supported by our R&D network.

We provide gas cylinders in a wide range of sizes and concentrations as well as gas handling equipment.

We also offer liquid gas storage solutions as well as on-site production systems.

Materials, manufacturing and assembly

Air Liquide has solutions for the production of raw materials, steel and aluminum rolls, and pipes.

We also offer associated services and equipment for manufacturing and assembly operations. For more information on our raw material production solutions, visit our metals industry page.

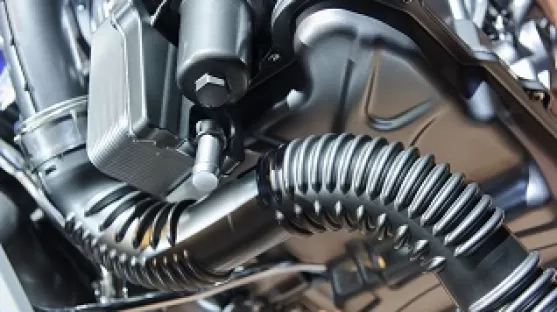

The manufacture of sub-components and the assembly of vehicles call upon numerous manufacturing processes for which Air Liquide defines the best gas solutions.

Maintenance, spare parts and recycling

The manufacture of sub-components and the assembly of vehicles call upon numerous manufacturing processes for which Air Liquide defines the best gas solutions.

The recycling of vehicles is an essential criterion for the recovery of materials.

Certain Air Liquide gas solutions can be used during the various recycling stages.

Supporting the key stages of automotive production

At Air Liquide, we rely on our know-how to adapt our innovations and our offers to the key stages of car manufacturing, namely the cutting of raw materials, heat treatment, laser cutting, welding arc and emission analysis.

The cutting of metal raw materials (sheets, tubes, coils and others) is the first step in the manufacture of metal structures and vehicle components.

Laser cutting is mainly used for thin sheets. Our LASAL™ solution combines pure, pre-mixed gases, strictly adhering to the laser manufacturer's specifications, with process gases to improve the reliability and performance of laser cutting operations.

The heat treatment of metals is a process which makes it possible to reinforce the resistance of the mechanical parts of vehicles. Our complete range of ALNAT™ metal heat treatment solutions includes gases, processing equipment and related services for high value-added processes.

Laser welding is the most productive thin material joining technology for the automotive industry. Compatible with standard CO2, fiber or solid-state lasers, our LASAL™ range uses the most suitable shielding gases: helium, argon or mixtures.

Arc welding is one of the most popular methods of joining vehicle components and structures. Compliant with ISO standards, our reference brand of welding gas ARCAL™ (argon and argon-based mixtures) is recommended for MIG-MAG and TIG processes.

Emissions analysis is a must for any automotive manufacturer . This process allows it to ensure that the exhaust gases from its vehicles comply with emission standards (Euro VI, EPA 1066, etc.). Our complete range of ALPHAGAZ™ specialty gases is perfectly suited for analysis and quality control. Our products are used by the automotive industry in the development, certification and manufacture of vehicles.

What is the current state of engine emissions testing applications?

Automakers are required to conduct increasingly rigorous engine emissions testing for new vehicles. They are forced to monitor and measure these emissions by national authorities, such as US (EPA) and European (commonly referred to as Euro) directives, which are the most common. As the manufacture and sale of automobiles is global, there is an increasing need to comply with both legislations, which imposes particular requirements.

What is the role of specialty gases in engine emissions testing?

Developing new engines for a vehicle takes four to five years and costs billions of euros. During this development, phase measurements of engine emissions are critical for R&D teams. Before the engine can be used in a car, it must undergo an intensive type approval process to ensure that emissions are below legal limits.

Manufacturers, their suppliers, and test centers use specialized analytical equipment that requires specialty gases to operate. These gases guarantee ultra-high purity and precision to ensure precise analyzes and precise and reliable analytical results.

What does Air Liquide offer for engine emissions testing?

Air Liquide's offer includes specialty gases with dual compliance and certification to EPA and EU standards. Indeed, Air Liquide is the first and only gas supplier to offer dual-compliance products that comply with US and EU regulations.

Our products are part of the ALPHAGAZ™ range , Air Liquide's premium specialty gas brand for analytical applications. The offering provides a comprehensive, yet simple, range of the most commonly requested pure gases and mixtures for engine emissions testing.

Specialty gases are used at all stages, from engine design and development to market approval, including road testing (RDE) and portable emission measurement systems (PEMS).

Do you have any questions abouot the automotive industry?

Please complete our contact form below and we'll come back to you as soon as possible.