Why use small essential gases in your water purification process?

- The intelligent use of essential gas molecules such as O2 and CO2 plays a vital role in putting the water industry on the path to a sustainable future.

- These natural solutions have the unique advantage of not causing additional emissions and waste to the environment, as is the case with conventional chemicals.

- It saves energy and carbon, which is why it is recognised as a future solution for the intensification of wastewater treatment.

- Water companies that produce recycled water or drinking water are showing increasing interest in using CO2, as it can demonstrate a reduction in carbon footprint.

- The use of O3 to treat micropollutants, bulk sludge and hard COD will appear in the future as a response to stricter legislation to meet the targets of the UK water environment regulations 2017.

- The ultimate goal of using essential small molecules is to help the customer achieve their Sustainable Development Goals (SDG's) and reduce their carbon footprint without compromising operational excellence.

Why choose Air Liquide for your water treatment gas installation?

High level of expertise and full support

- Experienced process engineers to assist you from design to implementation

Air Liquide is not a a molecule supplier, we also develop bespoke technologies that produce and/or use gases.

This means that Air Liquide supports its customers with the knowledge of its technical competence centre. They train the customer in the professional use of equipment and control cabinets. These chemical, mechanical or process engineers support the customer and optimise the design of their application.

- Comprehensive audits and follow-up campaigns

Apart from basic and design engineering, we also carry out extensive follow-up audits and campaigns. This includes analysis of your operations in order to optimise the process in a sustainable way. This is combined with follow-up campaigns for deeper support and assurance of implemented optimisations

- Process guide for the digitalisation of enterprise assets.

Finally, it is possible to assist the customer remotely thanks to Water 4.0 or the digitalisation of company assets.

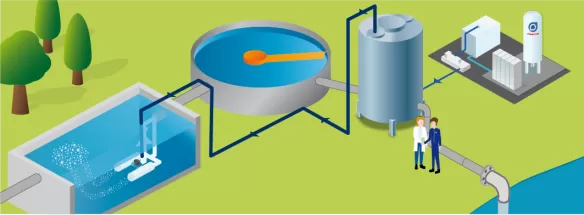

What equipment does Air Liquide offer for water treatment?

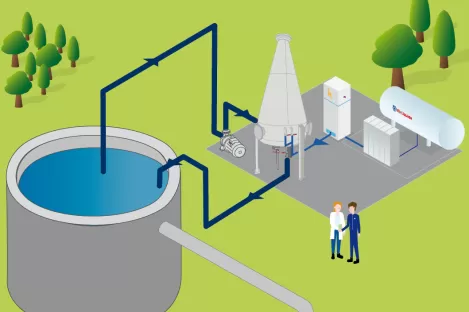

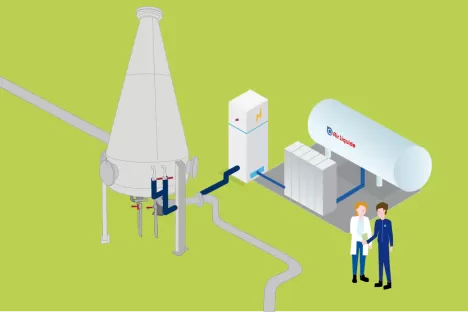

In addition to standard gas equipment such as regulators, transfer stations, hoses and valves, a special fleet of gas injection equipment and static mixers has been developed for water treatment.

Combining quality gas with the right equipment for your process will result in the best performance. Our team analyses, advises and supports solution integration.

An example of recent innovation:

The Ventoxal oxy-injector with high pressure nozzle

Discover our list of wastewater treatment plants

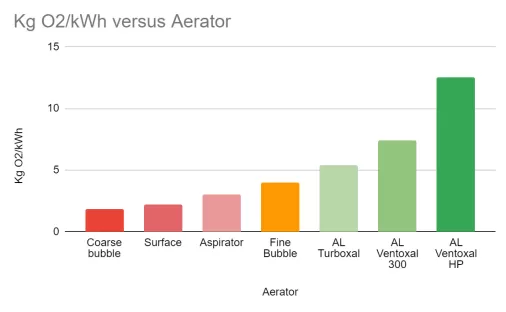

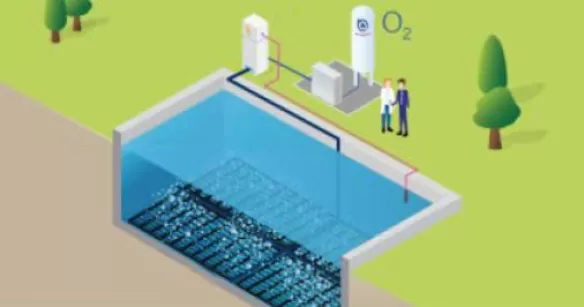

Submerged dynamic Oxy-Injector (O2) - Characteristics of the Ventoxal high pressure nozzle:

Mixing + Injection up to 14 Kg O2/h

| Rendu | Device | Asset type | Characteristics |

|---|---|---|---|

| Submerged dynamic oxygen injector (O2) | High pressure nozzle Ventoxal | Mixing + Injection up to 14 Kg O2/h |

| Ventoxal standard nozzle | Mixing + Injecting up to 7 Kg O2/h | |

| Oxy Injector Turboxal | Mixing + Injection up to 5.5 Kg O2/h | |

| Aqua Turboxal (RVS floating) | Mixing + Injection up to 5.5 Kg O2/h | |

| Immersed Static Injector (O2+CO2) | Poroxal | Energy-free, low investment costs |

Injector-Bicone | Wide range from 5 m³/h to 3000 m³/h | ||

| Cs-Nozzle | ||

| CO2 injection lance | Injection lance | |

| Reactors | Ozonation unit | Bespoke customer design |

|

Do you have any questions about wastewater treatment systems?

Please complete our contact form below and we'll come back to you as soon as possible.