Features and benefits

- Energy saving

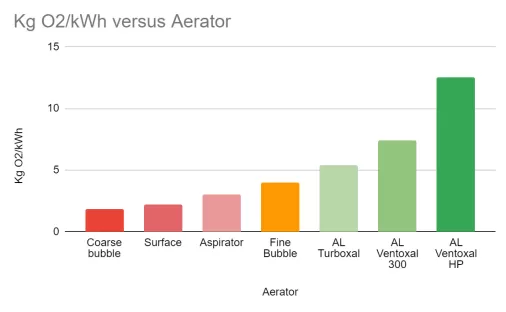

- High ratio kg of O2 injected per kWh for dynamic oxy-injectors

- 14kg of O2 for the newly developed Ventoxal 300 HP

- 7kg of O2 for standard Ventoxal 300

- 5kg of O2 for Turboxal HP

- No energy consumption with Poroxals, as these non-dynamic porous frameworks release O2 into the fluid via pressure gradients.

Energy efficiency of the oxygen injection system

- Carbon saving

- Removing excess gases from air injection can be an easy way to reduce VOC emissions

- With pure O2 there is no competition with air-nitrogen for solubility in liquid, the driving force is large.

- Henry's law teaches us that with high purity O2, the emission of CO2, CH4 & N2O can be reduced by up to 100 x.

Measurement of greenhouse gases from exhaust gases

- Operational comfort

- Low maintenance, only pumps or gear motors

- Stable operation throughout the year, regardless of seasonal changes

- Fully automated and continuous process

- No backup fan required

- High throughput without requiring large capital investments

- Optimum process control to meet the most stringent water permit limits

Equipment

The standard configuration of an installation is as follows:

- Customer

- Concrete slab

- Fences

- Consumables

- Pump

- Piping

- Control and dosing cabinet

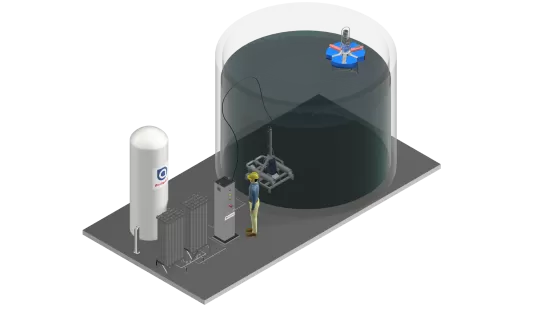

O2 installation with submerged Ventoxal mixer and floating Turboxal

After consultation with the customer and a technical study in which the optimum flow rates and O2 transfer efficiencies are estimated, the optimal injection concept is presented to the customer.

The following injection equipment can be selected:

- Ventoxal 300 HP

- Ventoxal 300 Standard

- Turboxal

- Poroxal

- Bicone

- In-line static mixer

- Lance

- Cs nozzle

Among the equipment and injectors mentioned above, Ventoxal and Turboxal are highlighted below:

An example of recent innovation: the Ventoxal oxy-injector with high pressure nozzle

The Ventoxal 300 with high pressure nozzle is an economical oxy-injector designed by Air Liquide, the injector provides high efficiency gas enrichment above.

The industrialisation and renovation of an existing property are successful thanks to the Ventoxal HP nozzle. This nozzle allows an energy gain of 50% compared to the previous Oxy-injector, equipped with the Cs nozzle.

A Ventoxal HP nozzle can transfer up to 14 kg/h of O2 in activated sludge water conditions.

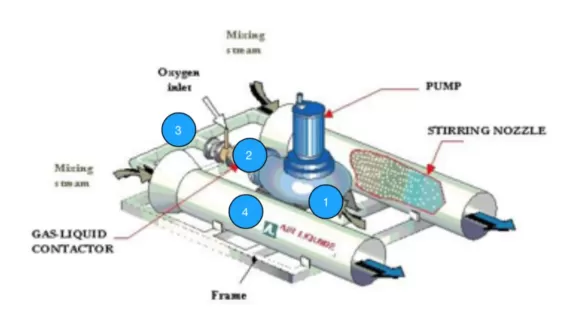

Ventoxal 300 before immersion

The Ventoxal is a compact stainless steel installation intended for use in waste water basins. The installation serves two purposes:

- Circulation of fluids = mixing.

- Liquid enrichment with oxygen.

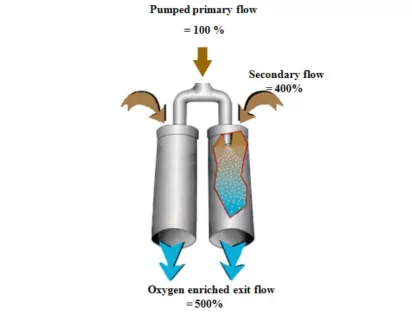

- The liquid to be enriched with oxygen is pumped (1) through a gas-liquid contactor (2), into which gaseous oxygen is injected.

Ventoxal Principle of action

The O2-enriched stream is re-injected into the basin (3) via 1 to 4 agitation nozzles (4) (depending on the model), which optimize total oxygenation and mixing. Due to the second mixing stage and the associated strong turbulence, very large amounts of oxygen can be dissolved.

- Very good transfer efficiency makes it possible to mix effluents.

- Well adapted to different levels of contamination

- Can be easily installed

- Requires easy pump supervision and maintenance

- Result: Increase in biological purification thanks to the use of pure oxygen which allows aerobic sludge to reduce odours, to cope with lack of capacity, to avoid foam, etc.

Principle of the ventoxal ejector

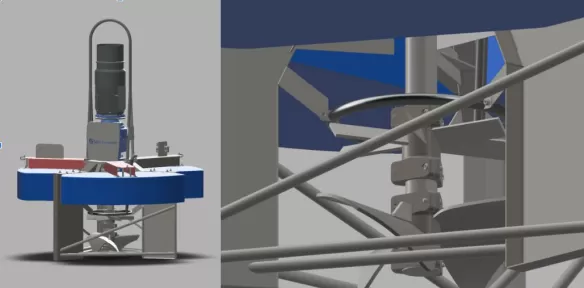

The Turboxal floating device oxy-injector offers high performance for the deoxygenation of wastewater in biological ponds and lagoons. Thanks to Air Liquide's patented system, effluent and oxygen are permeably mixed by a specific turbine in the biomass. The effluent is then dispersed downwards by a powerful paddle wheel, ensuring efficient transfer of oxygen to the wastewater.

- Floating surface oxygen injector &; Blender with bubble crown, blade and range

- To be used preferably in pools of limited depth (< 5 m)

- The turbine brings WW and O2 into contact

- Fine and dispersed bubbling stream

- To the bottom of the pool

- The high residence time of the gas bubbles leads to a large transfer.

- Injection up to 100 kg O2/h

- Mixed volume of 1500 m³

- Specialised control &; dosing cabinet

Services

Working with Air Liquides means benefiting from the support of a team of experts who offer you a whole range of services.

Standard audit:

- First meeting with the client: diagnosis.

- Factory tour

- Process research

- Performance Test

- Analysis

- Report with recommendations and tips to improve your process

Premium audit:

- Water Mobile App Integration

- Overview of water quality

- Collection of 9 parameters

- Online monitoring

- Full report with optimization suggestions

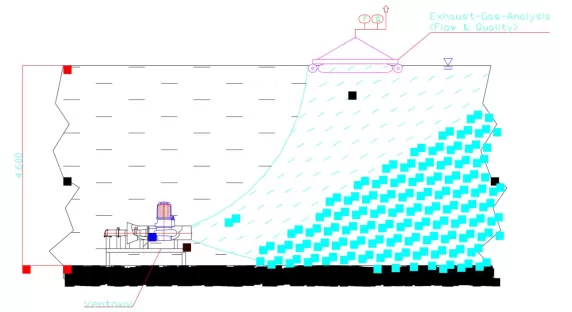

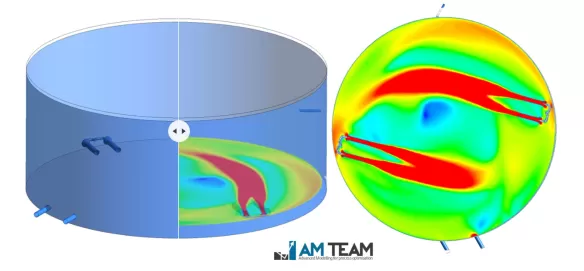

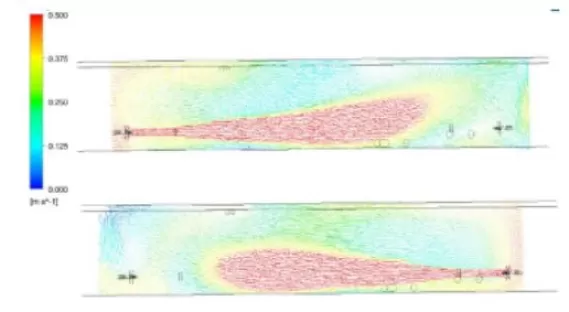

A new service that we can offer thanks to the ecosystem in which we work is CFD modeling.

AM-Team provides advanced modeling services for the water industry to save time, reduce costs and maximize process performance. AM-Team's unique blend of process understanding and advanced modeling expertise makes process and reactor simulations extremely accurate and valuable.

In order to design the process optimally from the start, CFD modeling generated an optimal location of 1 or 2 ventoxal units in the basin. The initial conditions were determined by Air Liquide in consultation with AM-Team.

In general, when using pure O2, the injected gas volumes are much smaller than in air-fed biological ponds and have a huge impact on the dynamics, which can be visualised with CFD modeling.

CFD model of a circular basin with 2 ventoxals

Flow pattern and velocity on the vertical section at the ventoxal location

Do you have any questions about biological wastewater treatment?

Please complete our contact form below and we will get back to you as soon as possible.