Comfort and convenience:

- The process is fully automated and from the supply to injection of the CO2 into the liquid

- No shower requirement as per traditional mineral acid treatments and no carcinogenic fumes are produced.

- Low-maintenance installation and valves make operation manageable.

Costs:

- The cost of CO2 is competitive with that of mineral acids

- It will reduce overhead operating costs (chemical and non-pumping operations)

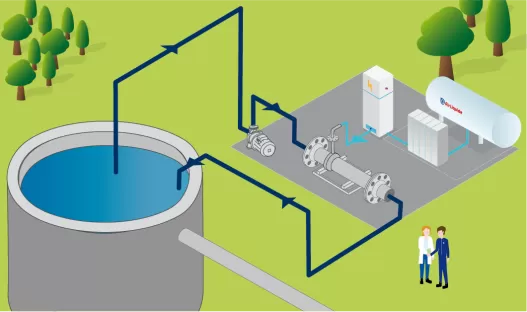

The standard configuration of an installation is as follows:

After consultation with the customer and a technical study in which the optimum flow rates and CO2 transfer efficiencies are estimated, the optimal injection concept will be proposed to the customer.

The following injection equipment can be selected:

- Bicone

- In-line static mixer

- Lances

- Turboxal

- Cs nozzle

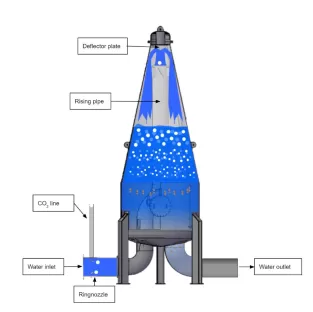

Among the static mixers and injectors mentioned above, we'll focus on the Bicone here:

The Bicone is an economical static mixer designed by Air Liquide. The injector provides high efficiency gas enrichment with minimal hydraulic loss. The static mixer is capable of dissolving various gases such as carbon dioxide (CO2), oxygen (O2) and ozone (O3) in water at the limit of saturation. This technology is very effective in process waters where the solubility of gases is limited by the operating conditions.

- Simple design

- Efficient gas solubility, even in process water

- Highly reliable technology

- Easy installation in existing installations

- Suitable for different water flows

- Minimal maintenance

- Transmission efficiency: 99% when used under the conditions of the specification table above.

Carbon impact CO2

ADVANCE, Air Liquide's new strategic plan for 2025, confirms its leadership in the decarbonization of industry and in the creation of a low-carbon society. Reducing CO2 emissions is a major challenge for players Of the industry. This represents a pool of opportunities for Air Liquide customers. It includes in particular the supply of low-carbon gases, but also solutions to transform the industrial processes of our customers. Air Liquide aims to reduce its emissions by a third by 2035 and to achieve carbon neutrality by 2050, while supporting its customers in their decarbonization process.

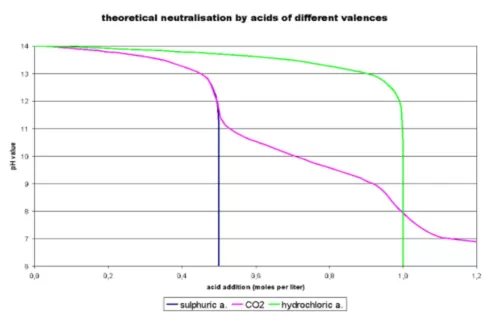

For the latter, a recovered gas like CO2 can be vital for the customer to improve the carbon footprint of their neutralization process. This could be thought of as the CO2 paradox: how CO2 reduces your footprint compared to mineral acids when neutralizing water.

This matters even more when the origin of the CO2 is a biogenic source, such as anaerobic digesters with biogas separation and CO2 recovery.

Considering the process, comparable footprints will be better due to the potential for CO2 sequestration. There is no loss of alkalinity, so no need for lime or caustic to adjust the pH in case of excess. Receiving waters welcome this essential small molecule because it plays a key role in the calcium-carbon balance of rivers and seas, it is also beneficial to micro-organisms and micro-algae. Finally, there are no emissions of harmful ions such as chlorides or sulphates which can be toxic for invertebrates.

Do you have any questions about pH adjustment and C02 neutralisation?

Please complete our contact form below and we will get back to you as soon as possible.