What modified atmosphere for the conservation of prepared fruits and vegetables?

Discover here the keys to extending the life of your products while preserving their organoleptic characteristics, without oxidation and without the use of preservatives, thanks to modified atmosphere packaging (MAP).

Young shoots, adult salads, raw vegetables, for cooking, in a short circuit or in a sustainable or certified agricultural sector, are foods that are on the rise. Preserving the quality and freshness of these fresh cut fruits and vegetables is a strategic issue for producers. But how do you condition them while they continue to breathe? This is the challenge of packaging in a protective atmosphere for so-called 4th range products.

Characteristics of 4th range products

Appearing in the 1980s on the fresh fruit and vegetable market, the products of the 4th range are now part of the daily food landscape. They constitute a set of vegetable products that are trimmed, peeled, cut and washed, making them “ready to eat” or “ready to cook” (but not seasoned). This name brings together various salad mixes (lettuce, chicory, lamb's lettuce) and grated vegetables (cabbage, celery, carrot), soup mixes and fruit preparations.

All these plants breathe and are exposed to various degradation processes (enzymatic oxidation, microbial development) which shorten their shelf life. Fresh fruits and vegetables remain living products once picked, and their lifespan is limited. When they are packaged in plastic film, the film limits the exchange of gases and water vapor that plants emit and also those that they need. The gases inside the packaging will be modified by their breathing and perspiration. The oxygen level will decrease while the carbon dioxide level will increase.

The degrees of modification of the atmosphere depend on:

- the type of fruits and vegetables that have different respiration rates and produce different gases. The more a plant breathes, the more difficult it will be to preserve it.

- their degree of maturity and/or senescence which affects their metabolism,

- of the temperature which affects respiration and the permeability of the packaging film. Their packaging, in order to increase their shelf life, must take into account the fact that they will continue to need oxygen,

- time, because their gas production can be modified by the accumulation of these gases in the atmosphere in the packaging.

Fruits and Vegetables classified according to their respiration rate

| Rate | Rate of respiration at 5°C (mg CO2 / Kg / h) |

Products |

|---|---|---|

| Very weak | <5 | Dried vegetables |

| Weak | 5-10 | Beetroot, Celery, Garlic, Onion, Potato (ripe), Bell pepper, Watermelon |

| Moderate | 10-20 | Cabbage, Melon, Carrot, Celery, Cucumber, Lettuce, Potato (new), Radish, Tomato |

| High | 20-40 | Carrot (with top), Cauliflower, Leek, Lettuce, Radish (with the top), Strawberry |

| Very high | 40-60 | Artichoke, Bean, Brussels sprout, Chicory, White onion, Watercress |

| Extremely high | >60 | Asparagus, Mushrooms, Broccoli, Parsley, Peas, Spinach, Sweet corn |

What is modified or protective atmosphere packaging?

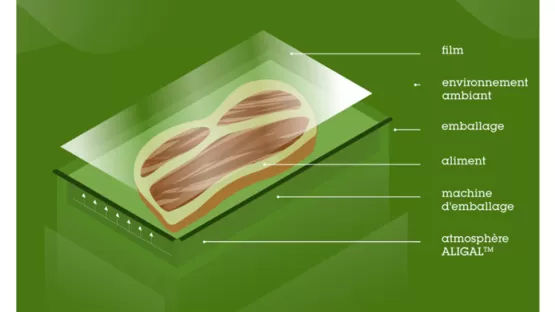

Modified Atmosphere Packaging (MAP) is a technique in which the gaseous atmosphere in a package is modified, that is to say different from the composition of the ambient air (20.9% O2, 78% N2, and 0.03% CO2). This modification allows the products to be in ideal storage conditions maintaining their initial freshness, colour, texture and nutritional qualities.

In the majority of cases, packaging is done with hermetically sealed packaging that is air and gas tight. But in the case of fresh cut fruits and vegetables, it is necessary that this technique be adapted to the breathing conditions of the products.

In the case of ready-to-use fresh plant products, the objective of packaging in a protective atmosphere is to:

- maintain adequate humidity around the product,

- reduce respiratory activity,

- delay ripening or maintain the state of maturity,

- delay or inhibit microbial growth,

- protect against shock.

By implementing a good atmospheric packaging system, shelf life of 6 to 9 days can be obtained depending on the product.

Which modified atmosphere to use?

Freshly cut fruits and salads, chicory, escarole, corn salad, lettuce (leaf, Iceberg lettuce), etc. are products with high humidity. Having a high respiratory intensity, they deteriorate very quickly after slicing or peeling. Browning phenomena, bacterial attacks and softening appear.

Prepared plants need oxygen to remain fresh until consumed. But too much oxygen also leads to the progressive deterioration of the cut leaves... The atmosphere must contain a quantity of around 2 to 8% oxygen, which makes it possible to maintain respiration but in a reduced manner and not to fall in anoxia or anaerobic conditions.

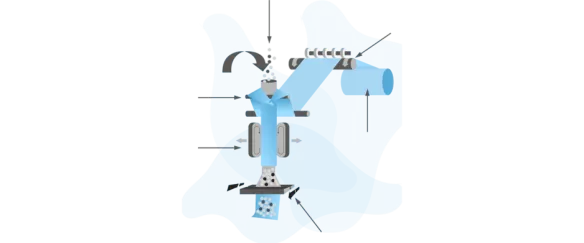

Enzyme degradation and activity can be slowed by adding the right amount of carbon dioxide (CO2) to the oxygen. The gas mixture, supplemented with nitrogen or argon, has advantages because it is even more efficient. The mixtures used are therefore ternary mixtures with for example 5% O2 / 15% CO2 / 80% N2. Already washed, ready-to-use products are very often presented in sachets, flowpacks and more recently bowls and trays in all formats, individual, family or for out-of-home catering. The most commonly used gas injection technique is sweeping. It is therefore easy to achieve the residual oxygen content by scanning and to only use a CO2/N2 mixture for injection.

Vertical bagging machine

Importance of the film

The objective is to maintain the correct concentration of oxygen and carbon dioxide in the packaging in order to obtain a balanced atmosphere (EMA Equilibrium Modified Atmosphere). Generally speaking, since films are not permeable enough for such applications, it is possible to adjust the permeability of the film to the respiratory intensity of the product, either via a previously microperforated film, or through in-line microperforation on the packaging machine.

Initially, a healthy product

The effectiveness of the process requires a relevant choice of the protective atmosphere, but also of the other elements of the system. To ensure successful packaging, the packaging machine, atmosphere and film are precisely matched to the product. This helps maintain the freshness and quality of fresh pre-packaged foods for as long as possible. But for total success, it is essential that the starting product is healthy, prepared under strict hygienic control, that the personnel and equipment respect health standards throughout the production chain, and that the chain of cold is respected.

Raw vegetables & vegetables

| Products | Mixture | TEMPERATURE | Time* | |||

|---|---|---|---|---|---|---|

| N2 | CO2 | O2 | Ar | |||

| Lettuce | 85 to 90 % | 8 to 10 % | 2 to 5 % | - | 4°C | 6-7 hours |

| Iceberg lettuce | 85 to 90 % | - | - | 4°C | 6-7 hours | |

| Endives | 85 to 90 % | - | - | 4°C | 6-7 hours | |

| Mixed Salad | 85 to 90 % | - | - | 4°C | 6-7 hours | |

| Baby leafs | - | - | 5% | 95 % | 4°C | 8 hours |

| Peeled potatoes | - | - | - | 100% | 4°C | 7-8 hours |

| Raw celery | - | - | - | 100% | 4°C | 7-8 hours |

* The DLCs are indicated for information purposes only.

If you want to bring a new product to market, no problem. From the choice of the form of supply, through the maintenance of the installations to the training of your employees, we offer you our assistance and know-how to discover the use of packaging gases.

With Air Liquide's international range of food grade gases, dedicated to the food industry, used on more than 1,500 different types of food products around the world, we have the right gas solution for your needs.

Do you have questions about modified atmosphere for preserving prepared fruits and vegetables? Please fill out our contact form.

Our experts will respond to you within 24 hours

Frequently asked questions

How to increase the shelf life of products?

What does “packaged in a protective atmosphere” mean on certain food packaging labels?

What are the different packaging machines for M.A.P?

What installation do I need to use gas?

What modified atmosphere for the conservation of fresh meats?

What modified atmosphere for bakery products?

What modified atmosphere for the conservation of seafood products?

What modified atmosphere for the conservation of cheese and dairy products?

What modified atmosphere for dry products?

What modified atmosphere for the conservation of prepared fruits and vegetables?