What installation do I need to use packaging gas?

Air Liquide explains how to package a food product in packaging containing gas, using a packaging machine.

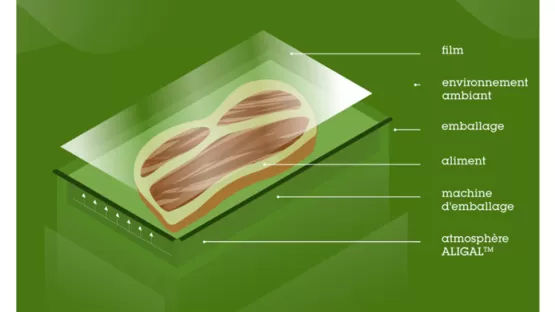

Modified atmosphere packaging, also called protective atmosphere packaging or MAP for “protective atmosphere”, is a process which consists of replacing the air present in the packaging with a suitable gas mixture.

It therefore involves packaging a food product in packaging containing gas using a packaging machine.

Its success is based on the combination of these elements:

- the characteristics of the product (recipe, hygiene)

- suitable gas atmosphere

- packaging material

- packaging machines

You have chosen your packaging, your packaging machine and validated its integration into your workshop. The quantity of gas you will need will depend on the size of your packaging, the type of machine used (vacuum reinjection or sweeping) and your production organisation.

Estimate your gas need in 3 steps

To estimate your annual gas requirement, it’s simple!

1. Estimate the volume of your packaging

The length, width and depth dimensions of your packaging allow you to calculate its volume in m3.

2. Estimate the unit gas/packaging requirement

Take into account the packaging technology: vacuum reinjection or gas sweeping

- Vacuum reinjection: Bell machine? : the gas/packaging requirement depends on the volume of the bell and the number of packages/cycle,

- Sealer? thermoformer? : the gas/packaging requirement corresponds to the volume of the packaging x3. Little tip, adding shims in the machine allows you to reduce the volume of the bell and thus optimize your gas consumption!

- Gas sweeping: Flowpacker? Vertical or horizontal bagger? : the gas/packaging requirement corresponds to the volume of the packaging x5. The lower the residual oxygen level, the higher the gas consumption will be to evacuate the air from the bag.

3. Estimate your annual gas need

Depending on the speed of your packaging machine and your production organization (number of packages/hour, number of hours worked/day, number of days/week, number of weeks/year), you will be able to determine your annual gas requirement.

Prepare your MAP installation

Whatever your annual gas needs and your conditioning process, your MAP installation will include:

- a gas source: gas cylinders or liquid storage with vaporization on site (atmospheric or electric heater for CO2).

- suitable expansion equipment: regulator, module or gas expansion unit for gases delivered in bottles.

- a distribution network up to the point of gas use

Contact our Air Liquide experts to size your installation and identify the necessary equipment.

The gas supply method adapts to your needs

Reliable gas supply is a priority for industry players.

Our teams work with our customers to identify the most suitable and competitive distribution method, based on the volume of gas required and their requirements in terms of purity, flow and safety.

Our objective is to offer first-rate logistics capable of satisfying everyone's specific requirements, with an optimal level of security.

- Cylinders and cylinder frames: For gas users requiring mobility and/or volumes not exceeding 5,000 m³ per month, cylinders represent a very practical method of gas supply. We offer a wide range of bottles adapted to your needs: S02, S05, S11, M20 or L50 (water capacity equivalent to 5 to 50 liters). Bottles can be grouped into baskets of 9 to 18 bottles to optimize transport and use.

- Liquid (on-site storage): Gas storage tanks in liquid form can be installed on your site if your needs and your production require it. Our teams supply, install and maintain these storage units. The gas stored in liquid form is vaporized by an atmospheric or electric heater system, and mixed via a gas mixer if mixing is necessary.

With a HACCP certified blender, continuously produce food grade N2/CO2 gas mixtures.

- On-site production: For very important needs our teams are at your disposal to study an on-site production solution.

Do you have questions about the different packaging machines for M.A.P? Please fill out our contact form.

Our experts will respond to you within 24 hours

Frequently asked questions

How to increase the shelf life of products?

What does “packaged in a protective atmosphere” mean on certain food packaging labels?

What are the different packaging machines for M.A.P?

What installation do I need to use gas?

What modified atmosphere for the conservation of fresh meats?

What modified atmosphere for bakery products?

What modified atmosphere for the conservation of seafood products?

What modified atmosphere for the conservation of cheese and dairy products?

What modified atmosphere for dry products?

What modified atmosphere for the conservation of prepared fruits and vegetables?