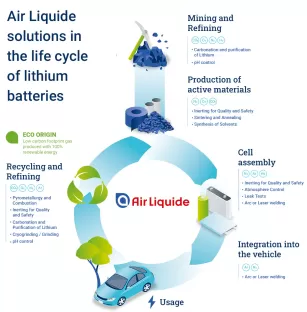

Solutions throughout the lithium battery life cycle

|

|

Adapted supply for gas always availableTo make it easier for you to manage the gases you use or to make it easier to maintain your compressors, Air Liquide offers you turnkey solutions, we offer you reliable and secure supply methods to meet all your needs, from cylinders to on-site gas production facilities and liquid storage tanks. |

|

|

In addition to gases, a wider range of services and expertiseSo that you can concentrate on your core business; our experts in inerting, heat treatment, welding, mining, gas atmosphere optimisation and effluent treatment are at your disposal to ensure the safety and optimization of your production. |

Building a European ecosystem for electric batteries

Critical role of gas

Gases are essential for the production and recycling of NMC lithium batteries (lithium ion batteries based on nickel, manganese, cobalt) or LFP (lithium ion iron phosphate batteries); they have a fundamental role in guaranteeing the performance of lithium ion cells: namely their lifespan, their stability, which improves the charging capacity of the batteries.

Air Liquide is at your service at each stage of the life cycle of electric batteries: from the mining and refining to the recycling and crushing of batteries at the end of their life where the gases contribute to ensuring the safety of operators and infrastructures.

Gas for more productivity and respect for the environment

Gases are an asset for the production and recycling of lithium ion batteries provided that their implementation and use are simple, safe and environmentally friendly.

On-site nitrogen or oxygen production ensures that gas is always available even when your gas demand varies. In addition, this solution minimises your carbon footprint and frees you from compressor maintenance problems.

To decarbonise your uses, the ECO ORIGIN offer for bulk gas guarantees you the use of gas produced with 100% renewable electricity.

Call Air Liquide if you are looking for simple and reliable solutions to control your gas consumption.

We bring you expertise through a global R&D network and experts

Our experts work on innovative solutions for the entire lithium-ion battery manufacturing chain and recycling, including optimisation of inerting atmospheres, cryogenic solutions for recycling, and effluent treatment.

Our experts can offer you or co-develop with you specific solutions. We can also adapt cryogenic solutions (nitrogen or carbon dioxide, rarely argon) for the recycling of batteries. Do not hesitate to call us to be contacted by Air Liquide experts.

Do you have questions about gas solutions for lithium batteries?

Please fill out our contact form.