- What distinguishes this old joining process?

- How does the joining process work? How are the materials joined?

- How is the oxygen-acetylene flame created?

- When is this welding technique used?

- Where can you buy gas for oxyacetylene welding?

- Where and how can you find out more about oxyacetylene technology?

What are the characteristics of the old gas welding joining process?

Among the types of gas welding, oxyacetylene welding is still the simplest method of joining two materials together. The aim of oxyacetylene technology is to join two metal components or materials together permanently. This is only possible with the addition of energy in the form of an open flame. The addition of specially alloyed welding wire is not essential for gas fusion welding.

How exactly does the joining process work? How are the materials joined?

Welding is simply the joining or bonding of materials. In this process, unalloyed or low-alloy steel is heated with an oxyacetylene flame.

In order for the welding flame to melt the metal, the oxygen-acetylene mixture must be heated to a very high temperature of up to 3,200°C. The components are joined together by melting the joints.

Gas welding is therefore also referred to as a joining process for connection welding.

How is the oxygen-acetylene flame created?

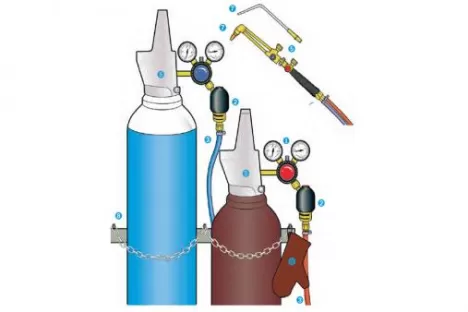

For oxyacetylene welding, you need at least one acetylene cylinder and one oxygen cylinder. With standard cylinders, a pressure reducer is screwed onto each cylinder to reduce the cylinder pressure to the respective working pressure. The two gas cylinders are each connected to the welding torch via a hose. Oxygen and acetylene are brought together in the torch and mixed there. You can then manually adjust the correct mixture of both gas types on the handpiece. First, a so-called neutral flame is set: Acetylene and oxygen are mixed in a ratio of 1:1 to 1.2:1. With this mixing ratio, the oxygen feeds the combustion on the one hand and also serves as an oxidising agent. The oxygen in the surrounding air cannot therefore combine with the workpiece. This prevents the formation of an oxide layer. The conditions for good welding are thus created. The setting of the welding flame depends on the material thickness of the workpieces to be welded.

When is this welding technique used?

Whether you are a professional or a hobby craftsman, the choice of the optimal gas welding process depends on the size and material of the workpieces as well as the requirements for the appearance and quality of the result. Of course, you also need the right welding equipment for each gas fusion welding technique. Therefore, in addition to the technical aspects, the economic aspects should not be ignored when choosing the type of gas welding.

As a rule, thin sheet metal constructions can be welded easily with little effort if the flame is correctly controlled. And if a little less precision is acceptable, welding with a gas flame is the right choice!

Oxy-fuel welding – material

- Unalloyed steel and low-alloy steel

- Non-ferrous metals

- Cast iron

- Material thicknesses up to 6 mm

Oxyacetylene welding – Areas of application

- Well suited for use on construction sites

- Particularly suitable for welding pipe connections

- In the installation sector

- For minor repair welding on fences, railings or furniture

Advantages of the process

- Easy availability of energy – welding with gas means you are not dependent on a power supply

- Can be used in all positions and locations – for example, when weld seams are difficult to access

- Easy handling of the equipment – even in awkward situations

- Easy to monitor the welding process – only welding goggles are required

- Cost-effective method – the investment costs for the equipment are comparatively low

Where can you buy gas for oxy-fuel welding?

Air Liquide is a strong partner! We offer a comprehensive range of industrial gases – not only for oxy-fuel welding, but for all applications. Our customers trust our high product quality, our application technology expertise and our excellent service. With around 650 sales partners, we are always close by throughout Germany. Especially when it comes to quick response times and regional expertise – our partners are always there for you. If you have any questions about:

- Renting or buying cylinders

- Daily billing of rental costs

- Flat-rate annual rental

- One-off purchase price of a gas cylinder

- Cylinder size and gas content

- Have it delivered or pick it up

Our partners have just the right answers and offers for you. Interested? Then take a look around!

Where and how can you find out more about autogenous technology?

Unfortunately, many companies now have very few welding experts when it comes to autogenous technology. Today's training programmes in the plumbing, heating and air conditioning trade no longer include intensive welding courses, as was previously the case. The relevant welding qualifications must be obtained in additional courses. In addition, welding tests are generally valid for a maximum of three years. As a result, young teams in craft businesses often lack the necessary know-how and experience.

The dangers involved in welding in particular should not be underestimated. Everything from connecting the gases to the welding equipment correctly and adjusting the gas flame to wearing the necessary protective clothing has to be learned. It can easily become dangerous if you overestimate your own abilities!

So if you want to try your hand at welding and have not yet mastered the art of oxyacetylene welding but would like to learn, you should definitely attend a course or consult an expert. Air Liquide offers support for all experts, users or anyone interested in welding technology. Interested? Then find out more about what we offer! We will be happy to advise you at the Air Liquide Welding Campus.

Oxy-fuel welding is a simple joining process and one of the original forms of welding technology. If you have the right equipment, all you need is the gas for welding. We offer acetylene and oxygen gas cylinders in all standard sizes – easy to order or pick up from one of our partners – even one near you!