- Why is metal inert gas welding with protective gas, such as aluminium welding, particularly important in shipbuilding and rail vehicle construction?

- What are the special requirements for MIG welding in shipbuilding and rail vehicle construction?

- Which gases and gas mixtures are used in MIG welding?

- Would you like to optimise your processes in the field of gas-shielded welding? We provide you with expert answers to your questions.

- Do you need further training?

MIG welding in rail vehicle and shipbuilding

The codes specified in DIN EN 24063 are used to precisely designate a welding process. In this particular case, it is welding process 131: metal inert gas welding with solid wire electrode.

Whether railway applications, rail vehicle parts, large ocean-going vessels, cruise ships, luxury yachts, ships for inland waterway transport or special ships for the offshore industry – all construction and tool parts are exposed to particularly strong vibrations, extreme weather conditions and high temperature fluctuations.

The range of steel materials (NE materials)

for all components must therefore be able to withstand corrosive attacks.

Extremely secure and strong connections are required here! Arc welding meets the special requirements.

Why is metal inert gas welding with protective gas, such as aluminium welding, particularly important in shipbuilding and rail vehicle construction?

Metal welding with inert gases is an arc welding process. MIG welding is mainly used for joining non-ferrous metals and alloys. These are metals and alloys such as aluminium, copper, zinc, nickel, titanium and brass.

In the MIG welding process, inert gas is supplied in addition to the welding wire. This shields the weld seam from the influence of the atmosphere (air) and thus prevents oxygen from entering the weld pool.

This prevents the risk of oxidation and creates the best conditions for strong, high-quality weld seams.

What are the special requirements for MIG welding in shipbuilding and rail vehicle construction?

The same welding equipment is used for MIG welding as for MAG welding. However, as particular attention must be paid to the wire feed when using very soft aluminium wires, suitable drive rollers and Teflon cores are used in the hose package for MIG welding.

The range of steel materials used for all components must be particularly resistant to corrosion.

Most of the steel joints in shipbuilding are made by manual welders. They require universal and powerful systems whose components are optimally matched to each other. Depending on the safety significance of the components or parts into which the welded part is integrated, different criteria are relevant.

For example, a typical requirement profile for shipbuilding is:

- Long seams

- deep penetration

- high cost-effectiveness

- High welding speed

Which inert gases and gas mixtures are used in MIG welding?

Inert, i.e. non-reactive gases such as pure argon and helium or mixtures of argon and helium are used. These gas mixtures reduce porosity, especially in thicker walls. This means that preheating is not necessary.

Adding different proportions of helium to argon results in deeper penetration and reduces the risk of pores and bonding defects. This also achieves a wider seam geometry.

A very small addition of nitrogen to argon or argon/helium mixtures stabilises the arc and thus not only influences the appearance of the seam but also reduces spatter formation.

With argon/helium mixtures, the welder requires a higher minimum amount of shielding gas. This means that a higher flow rate should also be set on the pressure regulator. We recommend additionally checking the flow rate with a gas measuring tube. The welding voltage should also be set higher as the helium content increases.

Since the gases used do not react with the base and filler materials, MIG welding is mainly used for joining copper, aluminium or aluminium alloys and other non-ferrous metals/alloys.

In principle, copper, for example, is very easy to weld.

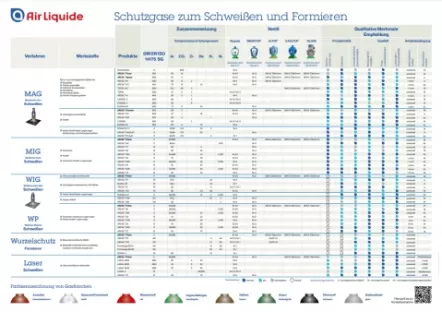

Workshop poster Shielding gases for welding and forming

This eliminates the possibility of oxidation of the weld seam. This is exactly the desired advantage.

The MIG welding process fully meets the high manufacturing requirements in the field of shipbuilding and rail vehicle construction:

- High process reliability

- Melting capacity and welding speed

- Optimal penetration conditions

Would you like to optimise your processes in the field of gas-shielded welding? We provide expert answers to your questions.

Air Liquide offers expert support to specialists, users and anyone interested in welding technology.

You may be familiar with MIG welding, but are you looking to optimise your gas-shielded welding processes or find answers to specific questions about welding aluminium or copper? Our team of experts can advise you and develop efficient solutions for you. There is almost always room for improvement!

Interested? Then contact us here with no obligation.

Do you need further training?

Our SchweisserCampus not only stands for safe applications and target group-specific training courses on welding seams and arcs, but also for training courses on welding processes such as MIG welding.

You are in good hands with our experienced welding engineers (SFI) and welding foremen. Our special expertise lies in making the best possible use of the properties of our gases. This also applies to welding materials with special requirements.

Other welding applications

MAG welding (metal active gas welding, gas-shielded welding) low-alloy steels

MAG welding (metal active gas welding, gas-shielded welding) high-alloy steels

MIG welding (metal inert gas welding, gas-shielded welding) in automotive and metal manufacturing

TIG welding

Laser welding

Laser hybrid welding

Plasma welding

Oxy-fuel welding / gas welding