- How the MAG welding process works

- Use of shielding gases for arc welding of unalloyed and low-alloy steels (e.g. structural steels)

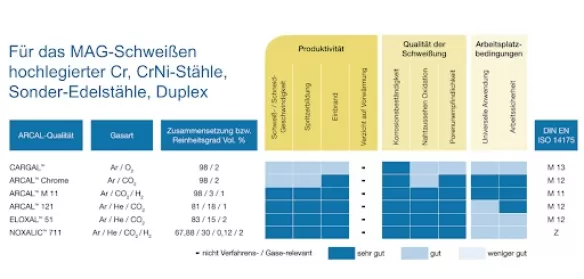

- Low-oxide metal active gas welding: Reduced active gas content for low-oxide MAG welding of high-alloy steels with very good weld seam properties

- Shielding gases for reducing smoke and pollutant formation during MAG welding of carbon steel

- Overview of suitable gases for gas-shielded welding

- Suitable pressure reducers for MAG welding of high-alloy steels

- Training courses and practical seminars for accident-free and safe working with the MAG welding process

- Videos and tutorials on MAG welding

- General and frequently asked questions about MAG welding of low-alloy steels

Originating from CO2 welding under carbon dioxide (in CO2 welding, carbon dioxide, the chemical compound of carbon and oxygen, is used as a shielding gas), argon mixed gases are now predominantly used for MAG welding. As a result, CO2 welding is increasingly being pushed into the background.

MAG welding is suitable for many different materials. Especially when MAG welding carbon steel, such as general structural steel, as well as unalloyed and low-alloy steels, the process ensures high cost-effectiveness and virtually limitless application thanks to its high automatability, the achievement of high welding speeds, the minimisation of rework and its low distortion.

The use of process gases can have a decisive influence on cost-effectiveness, productivity and product quality. Their physical and chemical properties open up a whole range of possibilities for savings and improvements.

How the MAG welding process works

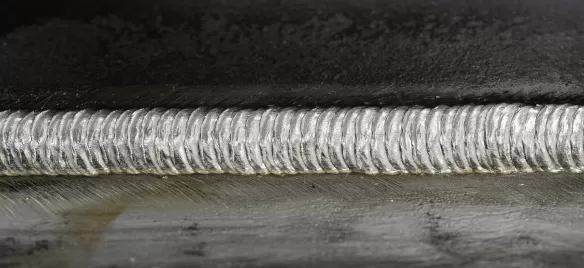

In MAG welding – in accordance with DIN EN ISO 4063, metal active gas welding with solid wire electrode, welding process 135 – the melting filler material, usually the welding wire, is fed mechanically by a wire feed system and melts in the arc. The welding wire ignites the arc the moment it touches the component. The melting filler material (wire) is used as material addition. To protect the arc from the reactive oxygen in the environment, a shielding gas also flows through the gas nozzle. This displaces the oxygen during welding and thus prevents oxidation at the arc and the weld pool.

Use of shielding gases for arc welding of high-alloy steels (e.g. chrome-nickel steels)

In MAG welding (welding process 135) of steel (structural steel), shielding gases based on argon and helium with additions of shielding gas containing active gas components (active gas as a reactive gas) in the form of carbon dioxide are used. In addition to protecting the weld pool from the atmosphere, the various shielding gases influence the type of material transfer, arc stability, penetration behaviour and oxidation of the weld seam. They also influence the development of smoke and pollutants.In MAG welding (welding process 135) of steel (structural steel), shielding gases based on argon and helium with additions of shielding gas containing active gas components (active gas as a reactive gas) in the form of carbon dioxide are used. In addition to protecting the weld pool from the atmosphere, the various shielding gases influence the type of material transfer, arc stability, penetration behaviour and oxidation of the weld seam. They also influence the development of smoke and pollutants.

Low-oxidation metal active gas welding: Reduced active gas components for low-oxidation MAG welding of high-alloy steels with very good weld seam properties

With ARCAL 14 or ARCAL 121, you can optimise the technological parameters, increase the melting rate, improve penetration conditions and reduce spatter formation or adapt it to the production conditions.

In many applications, the absence of spatter on the welded products is the decisive criterion – for example, in components for cooling systems, engine components or intake manifolds for turbochargers and pumps. With TERAL 24-7, Air Liquide has developed a process gas that is characterised above all by its low spatter: TERAL 24-7 significantly reduces welding spatter, ensures stable metal transfer and greatly reduces the tendency of the electrode to stick compared to conventional welding shielding gas. TERAL 24-7 primarily protects the weld pool. This alone can reduce downtime in the welding process by more than 60 per cent.

Shielding gases for reducing smoke and pollutant formation during MAG welding of carbon steel

Gases are mainly produced as reaction products from the gases and gas mixtures used and present. Particulate matter is mainly formed from the welding filler metal and the coatings used. There is also the welding fume emission rate: this indicates how much welding fume is produced in a given period of time. Depending on the process, it depends on various influencing factors.

In the MAG welding process of unalloyed and low-alloy steels, welding fume emissions initially increase with increasing current and then decrease again after reaching a maximum. Increasing argon or helium content in the shielding gas causes a decrease in welding fume emissions.

When welding steel with high carbon dioxide content, carbon monoxide is produced in potentially dangerous concentrations in addition to welding fumes, as well as ozone to a lesser extent. With ARCAL Chrome, Air Liquide has developed a shielding gas that is defined by its low carbon dioxide content. This results in low pollutant formation.

Overview of suitable gases for gas-shielded welding

The overview shows which gases are particularly suitable for gas-shielded welding for your objectives and materials.

The ARCAL shielding gas range helps you to increase the quality of the welded joint and the productivity of the welding process, as well as ensuring optimum working conditions. ARCAL quality gases are also available in the EXELTOP cylinder system with integrated pressure regulator.

Suitable pressure reducers for MAG welding of high-alloy steels

The inlet pressure plays an important role in MAG welding of high-alloy steels. A distinction is made between pressure regulators for 200 bar and 300 bar. The inlet pressure of the pressure regulator depends on the pressure of the gas cylinder and is tamper-proof thanks to different connections.

When MAG welding high-alloy steels, the design is based on the required amount of shielding gas in litres per minute. The adjustment range is selected from 0 to 30 litres.

Training courses and practical seminars for accident-free and safe working with MAG welding processes

MAG welding can pose hazards due to noise, smoke, electric current and fire. You must protect yourself from these hazards when welding. Among other things, flying sparks can occur or small pieces of slag can fly off the weld. These can be dangerous – not only for the worker, but also for the surrounding area. Particular attention should be paid to possible fire hazards.

- Trained employees are a prerequisite for working safely with gases during MAG welding in your company – and are required by law. Benefit from the extensive know-how and experience of Air Liquide's experts in technical gases.

- Do you want your employees to have the necessary knowledge to handle gases safely in order to prevent dangerous situations?

- Would you like to prove your employees' qualifications in handling gases?

- Do you want your employees to know the most important properties of the different gases?

- Are you looking for practical training courses that meet the requirements of the Occupational Safety and Health Act and the Industrial Safety Regulation?

Successful use of the MAG welding process depends on knowledge of the properties described here. Greater cost-effectiveness can be achieved by selecting the optimum gas. A mixed gas based on argon is normally used for MAG welding. The mixed gas contains small amounts of carbon dioxide as secondary components. The diversity and universality of the ARCAL shielding gases mentioned above has led to their dominant use. Helium additives extend the performance range.

General and frequently asked questions about MAG welding of low-alloy steels

What is MAG welding and how does it work?

MAG welding (metal active gas welding) is an arc welding process (process 135 according to DIN EN ISO 4063) in which a welding wire is fed mechanically and melted in the arc. A shielding gas protects the arc and the molten pool from the ambient air. It is mainly used for carbon steel, unalloyed and low-alloy steels.

What are the advantages of MAG welding of low-alloy steels?

MAG welding offers:

- high cost-effectiveness due to automatability

- high welding speeds

- Minimisation of rework

- low distortion

Which shielding gases are used in MAG welding of low-alloy steels?

As a rule, shielding gases based on argon and/or helium with additives of active gases such as carbon dioxide and/or oxygen are used.

The choice of shielding gas influences:

- The material transfer

- The arc stability

- The penetration behaviour

- The oxidation of the weld seam

- The development of smoke and pollutants

Can I also weld high-alloy steels with MAG welding?

Yes, there are processes such as "MAG welding" with reduced active gas content that are suitable for high-alloy steels.

The following are suitable for this purpose, for example:

- ARCAL Chrome

- Cargal

- ARCAL M11

- ARCAL 121

How can I reduce smoke and pollutant emissions during MAG welding?

By using shielding gases with low carbon dioxide content, such as:

- ARCAL 14

- TERAL 24-7

- CARGAL 3

can reduce the formation of pollutants.

Increasing the argon or helium content in the shielding gas also reduces welding fume emissions.

What role do pressure reducers play in MAG welding?

Pressure regulators are important for reducing the gas pressure from the gas cylinder to the required working pressure and ensuring a constant gas flow. When MAG welding high-alloy steels, the inlet pressure is important, and the design is based on the required shielding gas volume in litres per minute.

What safety precautions must be observed during MAG welding?

MAG welding can pose hazards due to:

- Noise

- Smoke

- Electric current

- Fire hazard

. It is important to protect yourself from these hazards, e.g. by wearing suitable protective clothing, extracting welding fumes and implementing fire safety measures.

What is the difference between CO2 welding and MAG welding?

O2 welding was the precursor to MAG welding, in which pure carbon dioxide was used as a shielding gas. Today, however, argon mixed gases are mainly used in MAG welding, as they deliver better welding results.

I have problems with welding spatter. Is there a solution?

Yes, with the process gas TERAL 24-7, Air Liquide has developed a shielding gas that is characterised by low spatter and enables a more stable metal transfer.

Other welding applications

MAG welding (metal active gas welding, gas-shielded welding) of high-alloy steels

MIG welding (metal inert gas welding, gas-shielded welding) in automotive and metal manufacturing

MIG welding (metal inert gas welding, gas-shielded welding) in rail vehicle and shipbuilding

TIG welding

Laser welding

Laser hybrid welding

Plasma welding

Oxy-fuel welding / gas welding