- How the MAG welding process works

- Use of shielding gases for arc welding of high-alloy steels (chromium-nickel steels and nickel-based materials)

- ARCAL Chrome, ARCAL 121 and He20µC: Interesting shielding gases for MAG welding of high-alloy steels

- Shielding gases for MAG welding of high-alloy chromium-nickel steels with ARCAL M11 – increased cost-effectiveness through higher welding speeds

- Overview: suitable gases for MAG welding of high-alloy materials

- Videos & tutorials on MAG welding

New requirements for material properties in terms of corrosion resistance, strength, attractiveness and weldability are the driving force behind further developments. The development of duplex and super duplex steels plays a particularly important role here.

Since such newly developed materials are usually also processed using welding technology, this regularly presents new challenges for manufacturers of power sources and filler materials, but also, of course, for developers of welding shielding gases.

High-alloy steel and nickel-based materials are increasingly being used in a wide variety of industrial and craft manufacturing applications due to their corrosion resistance and good processing properties.

The use of shielding gases can have a decisive influence on quality and cost-effectiveness due to the physical and chemical properties of the shielding gases. The shielding gases have a positive influence on the weld pool. Depending on the objective and material, a wide range of welding shielding gases is available. Here you can purchase the different gases for MAG welding of high-alloy materials.

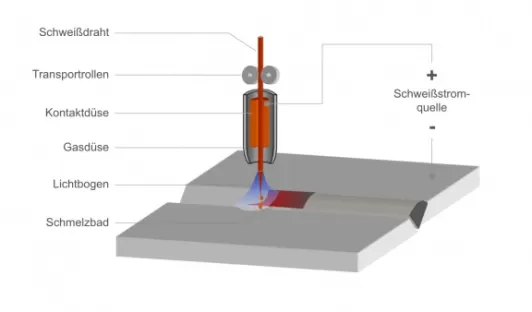

How the MAG welding process works

In MAG welding (metal active gas welding) of high-alloy steels – welding process 135 (DIN EN ISO 4063) – the melting filler material, usually welding wire, is fed mechanically by a wire feed system and melts in the arc.

The molten metal solidifies as it cools and forms a reliable bond between the components to be welded.

The welding area is protected from the surrounding atmosphere by the supply of process gases.

Argon, helium and mixtures thereof are used in arc welding of high-alloy steel, together with an additive active shielding gas component such as carbon dioxide. Impurities contained in the process gas, such as oxygen (O2), water vapour (H2O) and dust, etc., can influence the reaction. These impurities are undesirable.

High strength, good formability and good weldability are constantly expanding the range of applications for welding high-alloy steel. This applies in particular to components that come into contact with aggressive media or are exposed to the weather without protection.

Use of shielding gases for arc welding of high-alloy steels (chromium-nickel steels and nickel-based materials)

In MAG welding (welding process 135) of high-alloy steel (e.g. chrome-nickel steel), shielding gases based on argon and helium with low proportions of active gas (active gas as a reactive gas) such as carbon dioxide and/or hydrogen are used. Stainless steels are therefore mainly welded with gases from group M1 of the DIN ISO 14175 SG standard, which has been in force since 1 January 2009.

When arc welding these materials, the active gas content is significantly lower than when MAG welding unalloyed steels. This has an influence on the weld pool and the wetting behaviour. However, the higher oxidation sensitivity of high-alloy steels must be taken into account.

ARCAL Chrome, ARCAL 121 and He20µC: Interesting shielding gases for MAG welding of high-alloy steels

When MAG welding high-alloy materials, the influence of oxidation must be taken into account above all. The oxidation capacity causes discolouration on the weld seam surface.

Discolouration is caused by thermal oxides and occurs when heat and oxygen are present simultaneously. This generally results in reduced corrosion resistance. Since the oxidation capacity of oxygen is significantly greater than that of carbon dioxide, argon mixtures with carbon dioxide are primarily used here.

The three different process gases offered by Air Liquide each have their own individual strengths. This minimises the effort required for pickling.

ARCAL Chrome, for example, ensures high arc stability. With ARCAL 121, you can achieve a hotter arc thanks to the addition of helium. This makes it possible to achieve a higher melting rate and generate deeper penetration. ARCAL He20µC impresses with its low sensitivity to oxidation.

Shielding gases for MAG welding of high-alloy chromium-nickel steels with ARCAL M11 – increased cost-effectiveness through higher welding speeds

Thanks to its high melting rate and excellent seam quality, MAG welding with ARCAL M11 is considered an economical alternative to conventional process gases. The main component of ARCAL M11 is argon with small additions of carbon dioxide and hydrogen.

The carbon dioxide improves gap bridging and droplet detachment, for example in butt welds, and reduces the tendency to spatter. The hydrogen additive also increases welding performance and improves flow behaviour, seam transitions and flank wetting.

This gas is particularly advantageous for welding duplex and super duplex steels.

Overall, using ARCAL M11 as a process gas achieves higher productivity through faster welding speeds. The gas produces a more concentrated and stable arc. This improves penetration during welding and seam wetting.

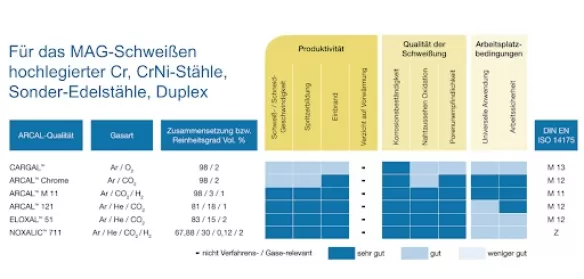

Overview: Suitable gases for MAG welding of high-alloy materials

The overview shows which gases are particularly suitable for MAG welding for your objectives and materials.

Conclusion

When MAG welding high-alloy steel, the specific characteristics of the steel in question and the required properties of the weld metal must be taken into account when determining the appropriate welding technology and selecting the wire-shielding gas combination. This is the only way to guarantee perfect weld quality and make optimum use of the advantages of the MAG process. The influence of the shielding gases on the weld pool can be used to positive effect here.

Trained employees are essential for working safely with gases when MAG welding high-alloy steels. Take advantage of our expertise and benefit from the experience of Air Liquide's technical gas experts.

When MAG welding high-alloy steel, the selection and correct use of the appropriate equipment also plays a decisive role. Take advantage of our product range or our recommendations for the correct selection and use of pressure regulators.

Other welding applications

MAG welding (metal active gas welding, gas-shielded welding) of high-alloy steels

MIG welding (metal inert gas welding, gas-shielded welding) in automotive and metal manufacturing

MIG welding (metal inert gas welding, gas-shielded welding) in rail vehicle and shipbuilding

TIG welding

Laser welding

Laser hybrid welding

Plasma welding

Oxy-fuel welding / gas welding