Shielding gases for laser keyhole/deep welding or heat conduction welding depending on the focus point and the size of the focal spot

Helium and argon shielding gases to prevent plasma formation during laser beam welding

Laser gases from Air Liquide: laser shielding gases and their advantages in laser welding and laser joining

LASAL for laser deep welding of steel, aluminium and titanium

Laser shielding gas nozzles: The LASAL™ nozzle concept for laser welding

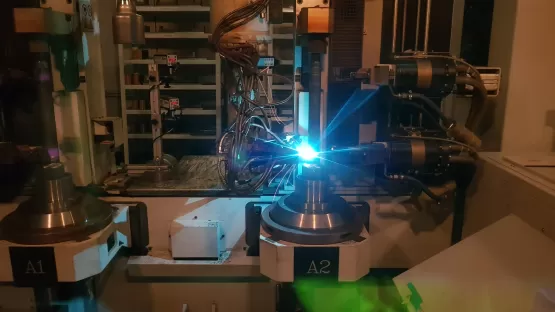

In laser beam welding (EN ISO 4063: Process 52), the energy from a focused laser beam with high power density [W/mm²] is used to rapidly heat materials and components to their melting temperature. This enables precise joining operations such as laser welding, laser brazing and build-up welding to be carried out.

The energy power density can be precisely adjusted to the joining task using focusing optics (laser optics/processing head). This allows components made of thin sheets to be welded, right up to thick-walled structural components. Laser joining is an established joining process in metal construction, vehicle, aircraft and shipbuilding, pipe and profile manufacturing, and machine, container and apparatus construction, and is an integral part of many manufacturing operations.

Shielding gas mixtures that are optimally adapted to the material, laser type and laser power ensure that the maximum laser power is transferred from the laser beam to the joining zone. This enables high laser welding seam quality and laser welding productivity.

Special features of gas lasers

Laser manufacturers specify resonator gases with precisely defined compositions and mixing ratios specifically for gas lasers (e.g. CO2 lasers).

In gas lasers, the resonator gas is the so-called laser active medium for generating the actual laser beam and is therefore an essential component of the laser application.

Air Liquide LASAL resonator gases are high-purity gas mixtures that far exceed the specifications of laser manufacturers in terms of mixing tolerance and homogeneity.

LASAL resonator gases thus ensure maximum laser beam stability throughout the entire operating life of the laser.

Shielding gases for laser keyhole/deep welding or heat conduction welding depending on the focus point and the size of the focal spot

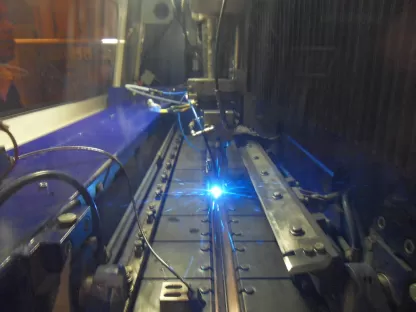

The laser power, laser wavelength, materials to be welded and type of laser welding (keyhole deep welding or heat conduction welding) used to perform the laser welding are decisive factors in the selection of shielding gases for laser welding.

The shielding gases adapted to the material and laser power have a significant influence on the welding result.

The heat transfer from the focal spot/focus point to the component surface and into the component, as well as the welding speed and shielding gas consumption, are directly related to the selected shielding gas.

The welding depth/penetration shape, the seam width-to-depth ratio, the seam surface and seam quality, as well as process stability and productivity can be directly and significantly influenced by shielding gases.

For a shielding gas to be efficient and effective, it is crucial that it arrives effectively at the intended welding point. The type of supply – i.e. the shielding gas nozzle – determines the potential for improving quality, safety and performance in laser welding.

Optimal shielding gases for laser welding can significantly improve:

- improve the process window

- reduce the formation of metal vapours, smoke, fumes and plasma tendency

- effectively shield the weld seam from environmental influences.

The shielding gas solution should be tailored to:

- the type of laser (fibre, diode, CO2)

- the laser power

- the laser wavelength

- the material and material thickness

- the required penetration geometry

- and the desired welding depth

Helium and argon shielding gases to prevent plasma formation during laser beam welding

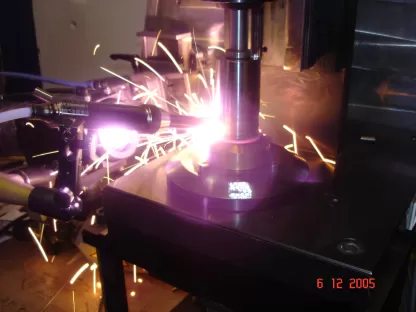

Plasma formation during laser welding is a disruptive effect. Plasma formation depends on the laser power and laser wavelength. The higher the laser power, the more susceptible the laser process is to plasma formation. CO2 lasers with a laser wavelength λ=10.6 µm are more prone to plasma formation than solid-state (fibre lasers, disc lasers) and diode lasers with their laser wavelength λ < 1.1 µm.

Helium is used in CO₂ lasers for initial use and at high laser powers. Argon is used in solid-state lasers (disc lasers, fibre lasers, diode lasers) regardless of the laser power and the material.

Compared to argon, helium has a smaller atomic diameter and higher ionisation energy, while also having a lower tendency to form plasma. The use of helium in high-power CO2 lasers ensures a more stable vapour capillary (keyhole) and prevents plasma formation. This enables good coupling of the laser energy into the component, resulting in a stable process.

The high thermal conductivity of helium also ensures effective heat transfer from the laser beam to the material. This results in a comparatively good welding depth, high welding speed and better wetting behaviour.

One of the most important functions of shielding gases is to effectively shield the melt in the joining zone from the ambient atmosphere so that no undesirable reactions with the ambient air can take place.

With argon and high-argon gases with a density > air density = 1.225 kg/m³, the ambient atmosphere can be achieved more effectively with a lower shielding gas flow than with shielding gases that are lighter than air. With argon and high-argon gases with a density > air density = 1.225 kg/m³, the ambient atmosphere can be achieved more effectively with lower shielding gas flow than with shielding gases that are lighter than air.

Laser gases from Air Liquide: Laser shielding gases and their advantages in laser welding and laser joining

Process stability and plasma formation can be significantly influenced by the gas composition, the type of laser and the laser power. When welding with 12 kW laser power, a gas mixture with at least 70% helium behaves similarly to pure helium in terms of stability and enables comparable welding depths. At a laser power of 2 kW, the minimum helium content required for a stable process is 20%. Due to the increasing challenges and diversity of laser joining applications and materials, e.g.:

- unalloyed and low-alloy steels,

- CrNi steels,

- aluminium,

- Ni-based alloys,

- copper

- Titanium, etc.

protective gas mixtures adapted to the material have proven effective.

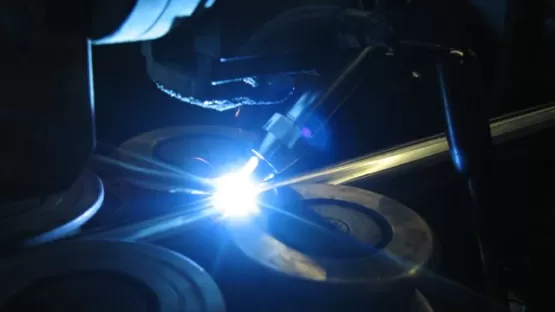

The LASAL 4633, LASAL 4635 and LASAL 4636 shielding gas mixtures protect the seam more effectively against undesirable atmospheric influences than is possible with pure helium as a shielding gas. At the same time, they enable higher seam quality, greater process stability and increased productivity.

In steel materials in particular, oxygen content in the shielding gas – regardless of the laser source and laser power – can improve the energy input into the component as well as the penetration behaviour and seam shape. Furthermore, better degassing, reduced tendency to pore formation and improved wetting of the seam flanks are beneficial effects on the laser welding processes. As a result, fewer notches are created, while welding speeds are increased.

LASAL for laser deep welding of steel, aluminium and titanium

LASAL 4633, LASAL 4635 and LASAL 4636 make it easier to weld materials with low absorption of the metallic surface, such as aluminium. Optimised coupling of the laser beams into the material stabilises the welding process and enables high welding depths and welding speeds over the entire length of the seam.

Optimised LASAL shielding gases significantly reduce gas consumption, thereby lowering process costs.

Laser shielding gas nozzles: The "LASAL nozzle concept" for laser welding

In addition to the selection of the shielding gas, the shielding gas supply is also of particular importance. The effectiveness of the gas or shielding mixture depends directly on whether it arrives effectively at the intended location. With LASAL nozzles, the physical and chemical properties of the shielding gases can be used to their full potential. This is crucial for precise energy input, process stability and seam quality.

LASAL shielding gases and LASAL nozzles together form an optimal combination for laser welding.

In the metalworking industry, argon and helium are traditionally used as welding shielding gases for laser welding. Depending on the material on the one hand and the type of laser, laser power and laser wavelength on the other, shielding gas mixtures can achieve better results while reducing process costs.

The potential of optimised LASAL shielding gases can be best exploited when they are combined with a coordinated LASAL nozzle delivery system to ensure that the shielding gas mixture is supplied to the welding process in the best possible way.

You may also be interested in

Hilf uns besser zu werden! Hinweise, Kritik oder Vorschläge?