The goal is to solder quickly and easily with the right flame temperature on the torch – whether you're working with steel, chrome-nickel, aluminium, copper, brass or bronze.

And the materials do not always have to be of the same type. A major advantage of soldering is that you can combine different materials. This is much more difficult with welding.

What does "brazing at eye level" mean?

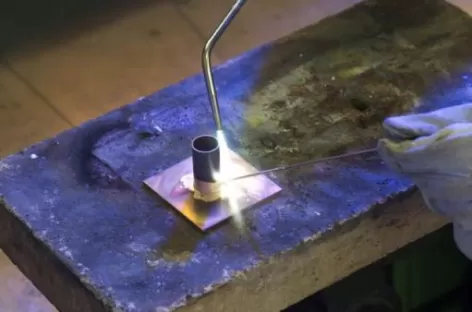

Despite modern joining techniques, autogenous brazing is a joining process you can rely on. You reach the working temperature with an optimum flame temperature so that your solder reaches the melting temperature. The workpieces are positioned before they melt.

This joining method has proven itself over time and remains a reliable method in the long term.

What do you need for brazing?

Our gases are available in various delivery forms. From very small, practical cylinders to large bundles. Or would you prefer a tank?

Everything coordinated – the right offer for every need.

How do you get your brazing accessories? Have you taken a look at our online portal? You can get everything you need there! That way, you're on the safe side.

Brazing – ready before it melts!

Why melt?

Unlike welding, where the base materials are liquefied or melted to join two or more parts, melting is not necessary in brazing.

In fact, it is not desirable for the base materials to melt. The parts to be joined are only heated at the points to be soldered.

To ensure that you can extract the correct amount of gas, you will need a pressure reducer, which you will have to purchase and install separately. Would you like to skip this step? Then we also offer an all-in-one solution with our products featuring an integrated pressure reducer. Druckminderer.

Once the pressure is set correctly on your burner, you can ignite your gas mixture. But be careful! This can backfire, literally. A flashback can trigger acetylene decomposition.

You must always be careful! For safety reasons, you have installed point-of-use templates on the gas cylinders to prevent this.

With a flame temperature of up to 3,200°C, you heat your workpieces to the working temperature specified by your solder.

The solder only begins to flow at the correct melting temperature. The solder wets both surfaces of the workpieces through capillary action, allowing the adhesion to exert its maximum force. Now let it cool down and you're done with the soldering.

With the soldering process, you can join two or more parts without melting them!

When brazing, the right flame is crucial!

You can obtain a neutral flame from a mixture of acetylene and oxygen. We supply both of these gases in cylinders.

What is a neutral flame? A neutral flame burns completely in a gas mixture of acetylene, oxygen and the oxygen from our air. No unburned acetylene or oxygen remains.

There are two other flame settings. One with excess acetylene and one with excess oxygen.

A flame setting with excess acetylene is called a soft flame. The flame cone is longer. But be careful!!! Acetylene consists, among other things, of carbon, which deposits as unburned coal and thus causes interference or contaminates our components.

A flame setting with excess oxygen is called a hard flame because the excess oxygen that was not needed for the flame can still react with adjacent substances. This may be desirable if it is additionally required.

Acetylene decomposition – how you can avoid it!

You can only avoid acetylene decomposition by strictly adhering to the safety rules for handling combustible gases and open flames! Then acetylene decomposition will not occur in the first place!

We offer training courses such as "Safe handling of gas cylinders". Afterwards, you won't need to worry anymore, because you'll be confident in what you're doing.

Conclusion

This joining method is very well established nowadays and is very reliable in the long term!

There are many different materials that can be soldered together. In addition, there is a wide range of solders to choose from. That is why practical implementation is sometimes not so easy. With us, you can practise hands-on!

Where is "here"? At the SchweisserCampus.

There, we have the opportunity to carry out practical exercises in brazing. We can also take a closer look and analyse your work in microscopic detail, for example. We look forward to seeing you!