Waste management / waste incineration areas of use

One way to make a combustion process more efficient is to add pure oxygen, which increases the combustion temperature and leads to a more complete combustion process. This reduces flue gas emissions and increases process capacity.

For thermal processes that require continuous adjustment of the combustion air, due to the variation of the calorific value of the fuel, the targeted supply of oxygen is a cost-effective solution to optimize combustion and respect the requirements in terms of emissions despite increased production. Air Liquide also provides a range of calibration gases for analytical instruments to ensure accurate analytical results.

Incineration of hazardous waste with oxygen

Oxygen is added in industrial combustion to achieve higher combustion temperatures, less incomplete combustion residues and/or cleaner flue gases. Particularly when hazardous waste is incinerated, the often dissimilar composition of the fuel can overload the installation and lead to the emission limit values being exceeded. A typical example is when the waste comes in packaging, eg barrels. Even in post-combustion, incompletely burned components are often present, resulting in short-lived emissions with high carbon monoxide values.

Together with our customers, Air Liquide has developed an efficient method of adding oxygen, which results in both lower carbon monoxide emissions and higher overall productivity.

Advantages:

- Improved combustion process

- Higher process temperatures

- Better CO afterburning

- Less heat losses

- Less flue gas

- Faster Responses

- Higher capacity of existing plants

- Greater flexibility for the factory

- Reduced specific consumption of support fuel

- Lower specific installation costs

- Low emission requirements are met

- Low investment costs

- Better return

Sludge combustion with oxygen

The use of oxygen increases the capacity of sludge incinerators while increasing efficiency.

To significantly increase the production capacity of sludge incinerators, oxygen is added, either directly or mixed into the combustion air. The individual adaptation of the oxygen technology to the specific boundary conditions of each installation results in both a higher capacity and a better efficiency, because different flow and combustion processes can be taken into account:

- The fluid rate is not undermined

- The bed temperature is kept constant

- Reactants are evenly mixed

- Easy to control endothermic reactions

Advantages:

- Higher efficiency/elimination of bottlenecks in existing installations

- Greater installation flexibility

- Reduced specific consumption of support fuel

- Lower specific fixed costs

- Meets or exceeds emissions requirements

- Low investment costs for renovation and new construction

- Low Specific Oxygen Cost

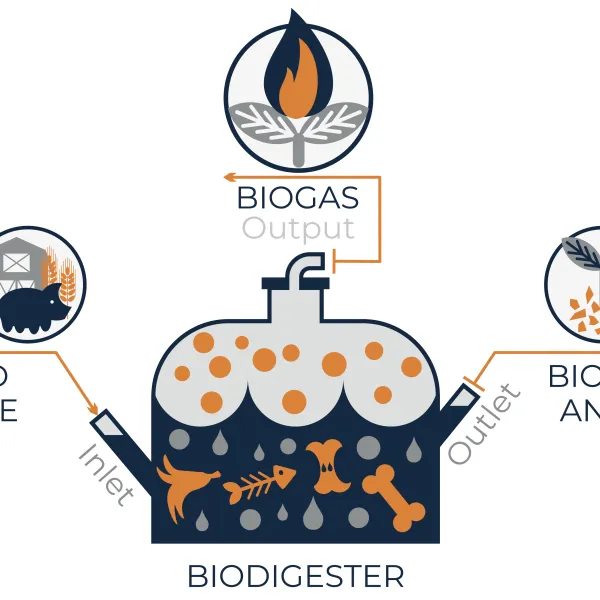

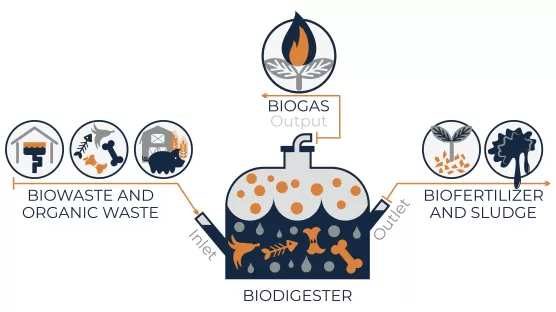

Waste to renewable energy

Air Liquide develops innovative technologies that improve processes in which waste is used to generate renewable energy and cleaner fuel in a sustainable way, such as a range of biogas upgrading technologies, such as membrane technology and various cryogenic applications.

Agricultural and household waste is used in biogas plants to produce a raw biogas, which must be upgraded if it is to be used as vehicle gas. This means that various substances such as water, carbon dioxide and hydrogen sulfide are purified.

Gases for waste management / waste incineration

Do you have any questions about waste management or waste incineration?

Please complete our contact form below and we'll come back to you as soon as possible.