The role of atmospheres for post additive manufacturing processing

|

|

SecurityDepending on the heat treatments, the atmospheres considered may contain, for example, hydrogen, hydrocarbons or use methanol for cementation. Strict compliance with the safety rules in force is essential. |

Air Liquide offer

The role of gases is preponderant in the various heat treatment processes. Through its expertise, Air Liquide supports you in their implementation.

The dusting of the powder as well as the removal of the supports

In the case of fusion on a powder bed, the dust removal operation is essential: mechanical, pneumatic, or by liquid / chemical means. This work can be manual or automatic to limit labor costs. The removal of manufacturing supports comes next in the production process.

Air Liquide expertise for heat treatments

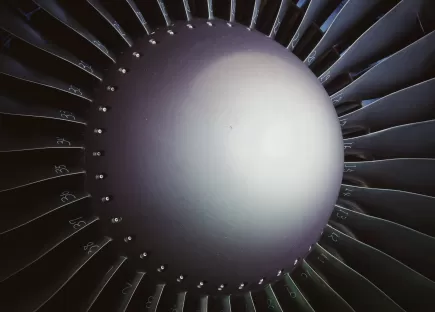

Finally, the heat treatment of the metal parts makes it possible to eliminate the residual stresses, created within the material during the manufacturing process, and to ensure the required quality in terms of mechanical properties.

The solution generally adopted consists of installing heat treatment equipment such as stress-relieving furnaces in additive manufacturing workshops. Flow organization and management are thus improved, optimizing productivity, costs and lead times.

For sensitive alloys, this heat treatment step is often carried out under an inert atmosphere using a neutral gas such as nitrogen or argon. Air Liquide's heat treatment experts are also there to help you define the cycle times and temperature to be applied to the load.

Heat treatment of your metal parts

In order to obtain the final mechanical properties, additional thermochemical treatments are sometimes necessary: carburising or nitriding can for example increase the hardness. These different operations can be carried out by service providers specializing in heat treatment.

Here again, the main role of the gaseous atmosphere is preponderant: the Air Liquide offer for heat treatment addresses all of your needs.

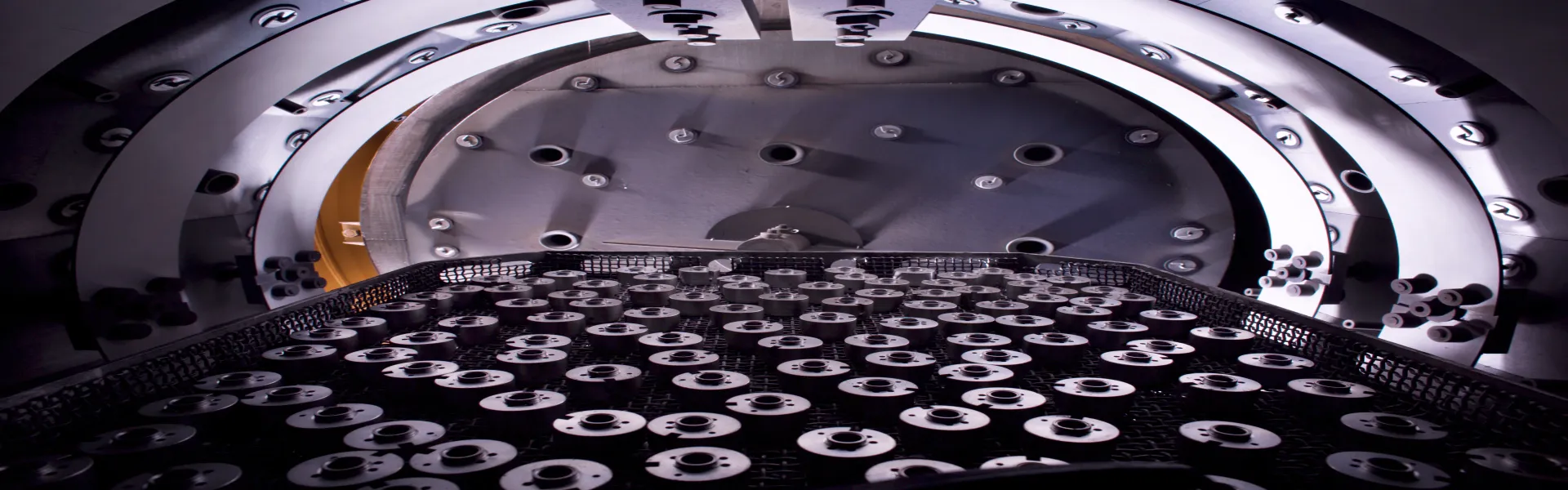

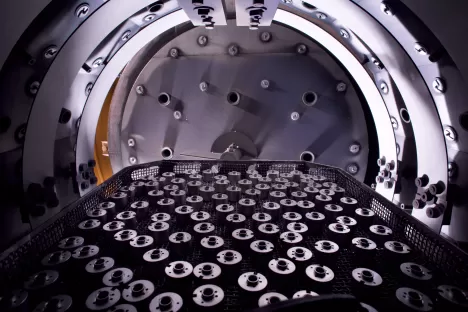

Hot isostatic compression of your parts (HIP)

Finally, for the most demanding metal parts, it may be important to maximise compactness. This is the goal of Hot Isostatic Pressing (HIP). The parts - some even of large dimensions - are housed in an enclosure and subjected to very high pressure (up to several thousand bars), at high temperature (several hundred degrees).

Argon is mainly used and still has a crucial role here. While purity is important to avoid oxidation, processing under given conditions of temperature and pressure requires special attention.

Do you have any questions about post-additive manufacturing treatments?

Please fill in our contact form below and we'll come back to you as soon as possible