Alpro commissions large-scale water reuse installation

Air Liquide supplies sustainable pH control system

Alpro – part of the Danone food company – has commissioned a water reuse installation with an annual purification capacity of 930,000 m3 at its site in Wevelgem. Thanks to this installation, some 80% of wastewater can be reused.

The plant was designed and built by De Watergroep, the largest potable water company in Flanders providing services throughout the whole water chain. De Watergroep also uses its experience and knowledge to work on customised projects for companies. "We not only take care of the installation’s design and construction, but in many cases – as at Alpro in Wevelgem – we’re also responsible for the operational part and maintenance," explains Dylan White, De Watergroep Project Manager, Industry & Services.

"The idea is that we completely take the worry away from our customers, both on the technical side and on quality. There’s a 24/7 on-call service and we monitor all the relevant parameters remotely via a Scada system."

Sustainable and cost-saving

The installation means that more potable water is now available for other customers in the area. Reusing the water ensures that the potable water bills at Alpro’s Wevelgem factory will be considerably lower from now on. The reduction is such that installation cost payback will come in the foreseeable future. "It goes without saying that an approach where sustainability can be combined with cost savings is particularly attractive," White confirms. "So, we expect a sharp increase in this type of installation in the near future."

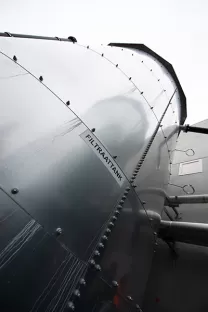

The plant's filter units and control electronics are in a concrete annex to the Alpro site. Adjacent to the building are several water tanks, a CO2 tank, and a bicone device that injects CO2 into the water and mixes it. But before the wastewater is directed to the plant, it first undergoes treatment in a purification basin. This basin was already used to purify wastewater long before there was talk of a water recycling plant.

pH correction with CO2

"The first thing we do when the wastewater – which has already undergone initial treatment – arrives at the water recycling plant is to correct the pH value by adding CO2. This is a necessary step, because otherwise the ultrafine pores of the reverse osmosis filtration - further on in the process – would clog up due to calcification.”

"In the past, only aggressive acids such as sulphuric and hydrochloric were used for this, but CO2 is more sustainable and is often more economical at larger water volumes. Carbon dioxide has a footprint three to four times smaller than the other technologies – it is clearly recovered CO2, so there are no additional emissions – and it makes process management easier."

"The CO2 installation was put in place in close consultation with Air Liquide water specialists. Air Liquide provides significant added value in this type of project, thanks in part to their extensive knowledge in this area."

Once the pH has been optimised, larger organic material and floating particles are filtered out of the water using coarse filters in a first phase. In the next phase, the water is further purified using an ultrafiltration system. And finally, the water is purified one last time in a filter system based on reverse osmosis. The previously added CO2 is then removed from the water, after which it is ready to be used again.

Triple zero

Dominique Hamerlinck – Alpro’s Divisional Energy and Utility Manager – explains how the water reuse system fits into Danone's 'triple zero' philosophy: "Danone and Alpro want to reduce environmental impact according to the ‘triple zero’ model, in terms of energy, water, and waste. Here at our Alpro site in Wevelgem, we’ve developed a system to reuse as much wastewater as possible."

"This water stream is completely separated from the water we use in our products. We can’t recover that water, because it leaves the factory as an ingredient in our products."

"As for pH correction in our water reuse plant, we chose CO2 in consultation with De Watergroep. This is primarily because CO2 offers by far the smallest footprint in terms of environment and emissions. CO2 also ensures that the residual fraction that’s discharged – the part of the water that can’t be recovered, for example – is much more environmentally friendly than if chemicals were used."

Contact us for more information on re-using wastewater.