- MIG welding (metal inert gas welding) in industrial applications – good automatability, high melting rate and welding speed

- How the MIG welding process works

- MIG welding (metal inert gas welding) of non-ferrous metals – the important role of process gases

- ARCAL 31 N – process gas for high-quality arc welding of non-ferrous metals

- Suitable pressure reducers for MIG welding (metal inert gas welding)

- Training courses and practical seminars for accident-free and safe working with the MIG welding process

Metal inert gas welding in industrial applications – good automatability, high melting rate and welding speed

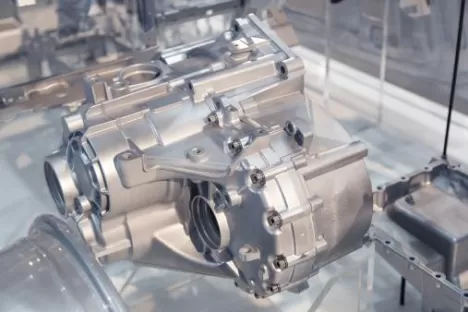

MIG (metal inert gas) welding is one of the best-known welding processes and is used primarily in industrial applications, particularly in the automotive industry. Quality and productivity are the main priorities in MIG welding (metal inert gas welding).

The process is characterised by its high degree of automatability, the achievement of high welding speeds and high melting rates, as well as the assurance of high quality.

The use of process gases can have a decisive influence on cost-effectiveness, productivity and product quality. Their physical and chemical properties open up a whole range of possibilities for savings and improvements.

How the MIG welding process works

In metal inert gas welding (welding process 131) of non-ferrous materials – welding process 131 (DIN EN ISO 4063) – the melting filler material – the welding wire – is fed mechanically by a wire feed system and melts in the arc.

The molten metal solidifies as it cools and forms a reliable connection between the components to be welded.

During the MIG welding process, shielding gas is supplied through a nozzle. This prevents oxygen and contaminants from the atmosphere from entering the weld pool and thus protects the molten pool from oxidation.

The supply of process gases protects the weld site from the surrounding atmosphere.

Inert gases such as argon, helium and mixtures thereof are used for arc welding of materials such as non-ferrous metals such as aluminium, copper or titanium. Contaminants contained in the process gas, such as oxygen (O2), water vapour (H2O) and dust, etc., can influence the reaction. These contaminants are undesirable.

MIG welding of non-ferrous metals – the important role of process gases

Inert gases such as argon, helium and mixtures thereof play an important role in metal inert gas welding. The gases used do not react with the base and filler materials.

New requirements for the properties of non-ferrous metals are driving the further development of welding processability. A thin oxide skin and a clean surface that ensures a stable arc are prerequisites for MIG welding.

ARCAL 31 N – Process gas for high-quality arc welding of non-ferrous metals

Pure argon was used as a shielding gas for aluminium welding. However, attempts were made early on to compensate for the disadvantages of pure gas by adding additives.

The addition of helium results in a higher arc voltage and thus a higher heat input into the workpiece. Nitrogen, on the other hand, can significantly improve penetration during welding.

These technical findings have been significantly improved with ARCAL™ 31 N as a process gas.

The doped nitrogen content has an effect similar to that of helium:

- the penetration becomes deeper,

- porosity is reduced,

- arc stability improves,

- there is more concentrated heat input,

- and there is less spatter

Suitable pressure reducers for MIG welding

The inlet pressure plays an important role in MIG welding. A distinction is made between pressure regulators for 200 bar and 300 bar. The inlet pressure of the pressure regulator depends on the pressure of the gas cylinder and is tamper-proof thanks to different connections.

In MIG welding, the design is based on the required amount of shielding gas in litres per minute. The adjustment range is selected from 0 to 30 litres.

Training courses and practical seminars for accident-free and safe working with the MIG welding process

MIG welding can pose hazards due to noise, smoke, electric current and fire. You must protect yourself from these hazards when welding. Among other things, flying sparks can occur. Small pieces of slag can also fly off the weld. These can be dangerous – not only for the worker, but also for the surrounding area. Particular attention should be paid to possible fire hazards.

Trained employees are essential for working safely with gases during MIG welding in your company – and are required by law. Benefit from the extensive know-how and experience of Air Liquide's experts in technical gases.

Do you want your employees to have the necessary knowledge to handle gases safely in order to prevent dangerous situations?

Would you like to prove your employees' qualifications in handling gases?

Do you want your employees to know the most important properties of the different gases?

Are you looking for practical training courses that meet the requirements of the Occupational Safety and Health Act and the Industrial Safety Regulation?

Successful use of the MIG welding process depends on knowledge of the properties described here. Greater cost-effectiveness can be achieved through the optimal selection of gases. A mixed gas based on argon (inert gas) is normally used for MIG welding. The diversity and universality of ARCAL 31 N as a shielding gas has led to its dominant use. Helium additives extend the performance range.

Unsere Broschüren zum Metall Inertgas Schweißen

Other welding applications

MAG welding (metal active gas welding, gas-shielded welding) low-alloy steels

MAG welding (metal active gas welding, gas-shielded welding) high-alloy steels

MIG welding (metal inert gas welding, gas-shielded welding) in rail vehicle and ship construction

TIG welding

Laser welding

Laser hybrid welding

Plasma welding

Oxy-fuel welding / gas welding